Specialized | Carbon 3D Saddle

Industrial Design Lead 2019-2021

Industrial Design

CAD Sculpting

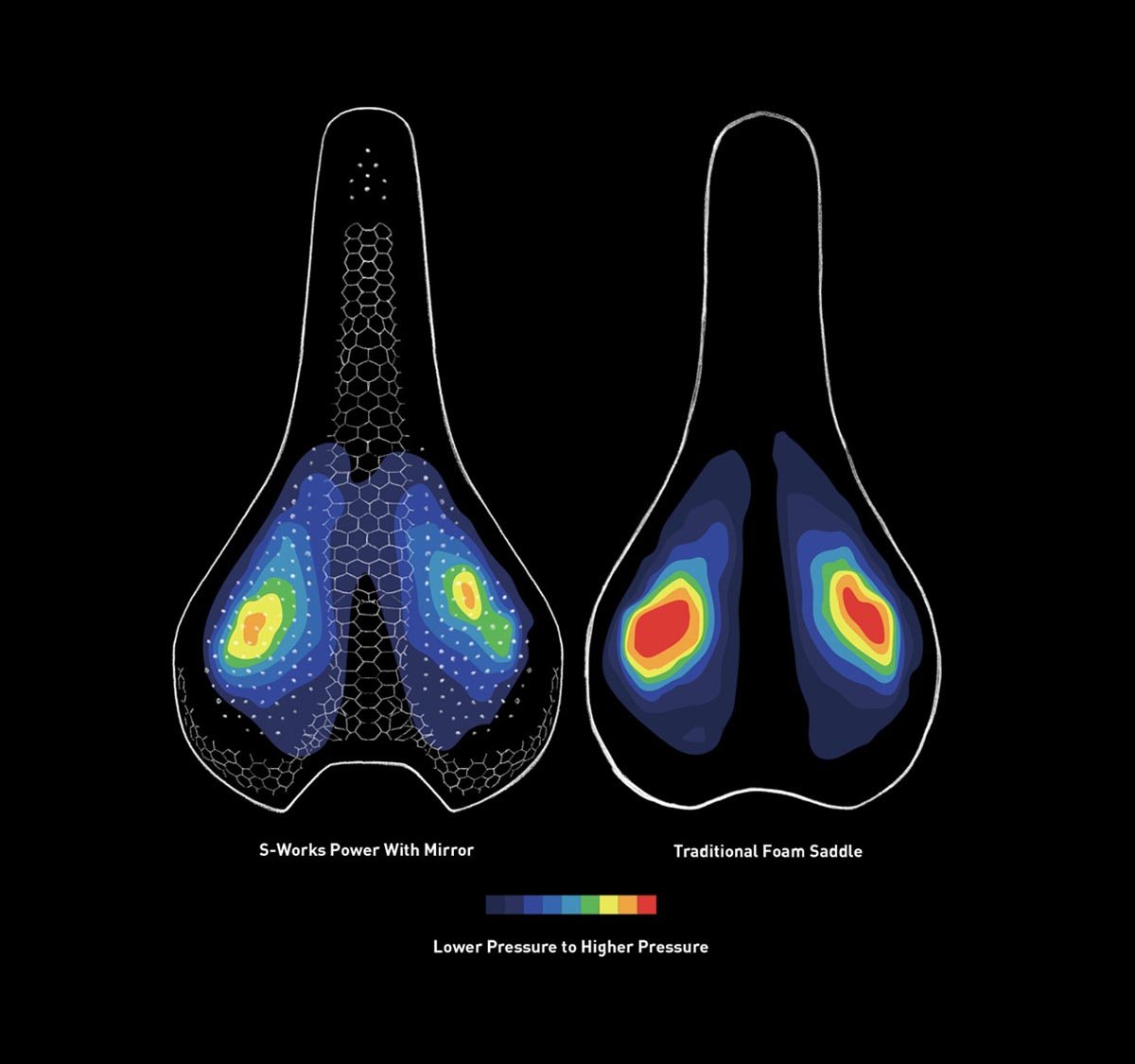

I was part of an amazing team of engineers and material scientists that help designed and developed the Specialized Power and Romin saddle. Their first ever digitally printed lattice bike saddles designed to improve rider comfort and performance. It’s crafted using Carbon materials and complex lattice geometries. It absorbs impact and improves stability, which can reduce the chance of injury for the rider. Unlike traditional single-density foam, Carbon’s Lattice design allows for infinite density tuning with a single material.

“Equally impressive as the technology itself, Carbon DLS is helping to bring saddle designs to market at record speed. Together, Carbon and Specialized were able to reduce the overall development process from the typical 18-24 month timeline to just 10 months, while still creating and testing over 70 designs in this short timeframe. The use of Carbon technology reduced the overall design process from 6 to 2 months, with design iteration, which typically takes 2-3 weeks, taking only 1 day with Carbon. Broadly, the Carbon DLS process provides product teams with powerful capabilities to achieve vastly accelerated design and development timelines, enabling better products to go to market much faster than with other design and manufacturing approaches.” - Carbon