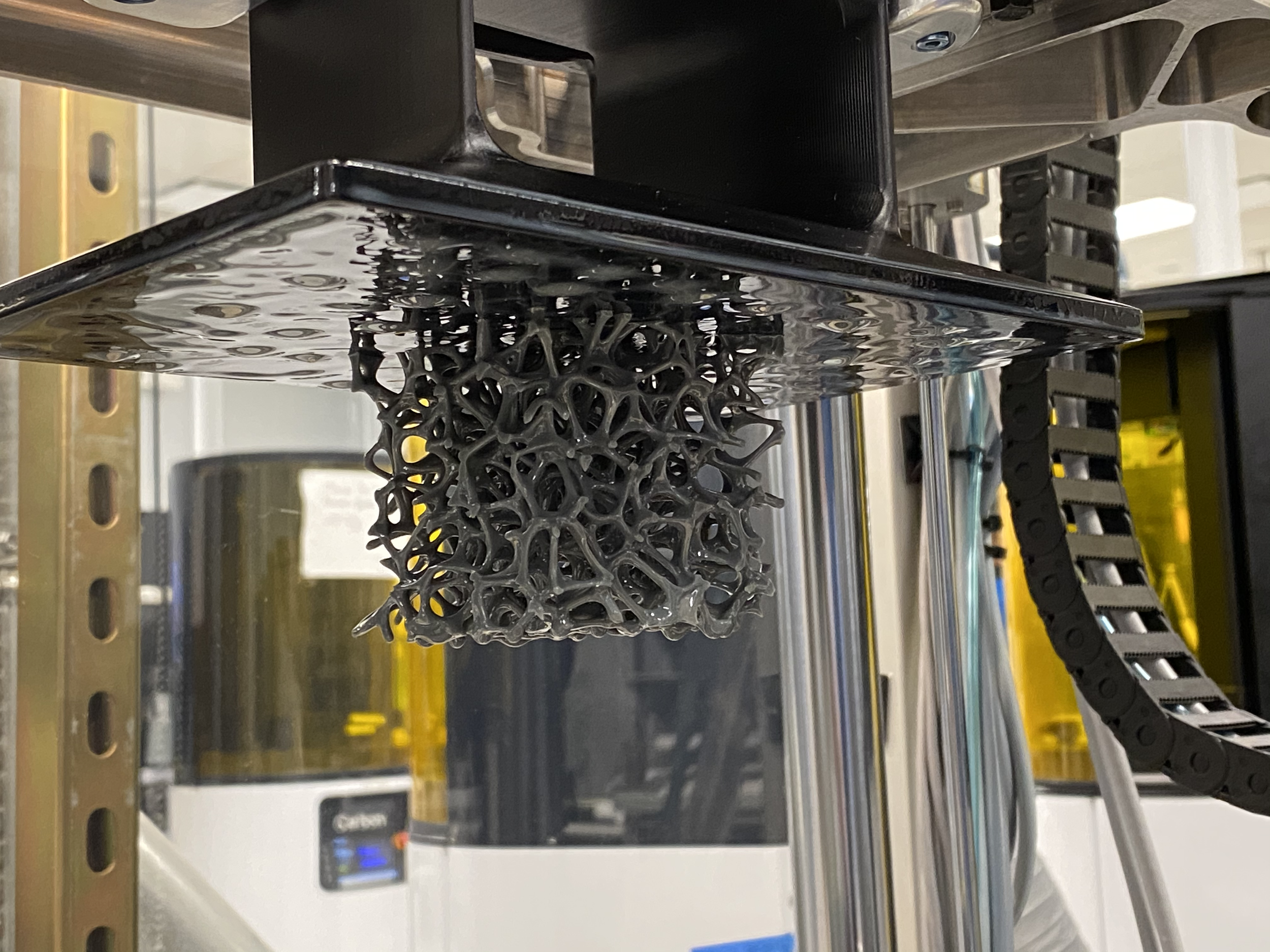

Carbon M3 Printer

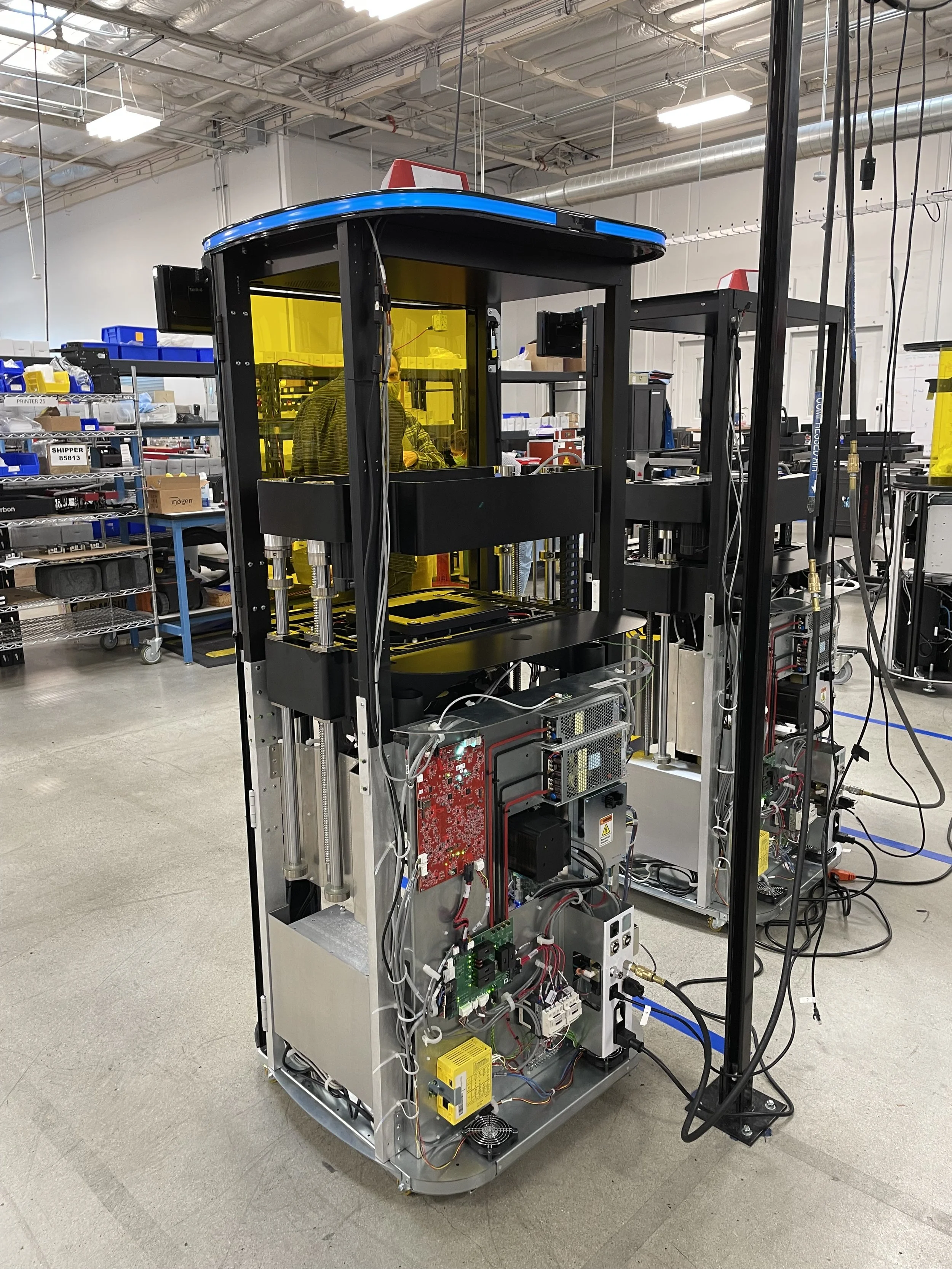

Sr. Staff, Industrial Design Lead 2021-2023

Industrial Design

Project Management

UI.UX Research

HMI Design

Overview

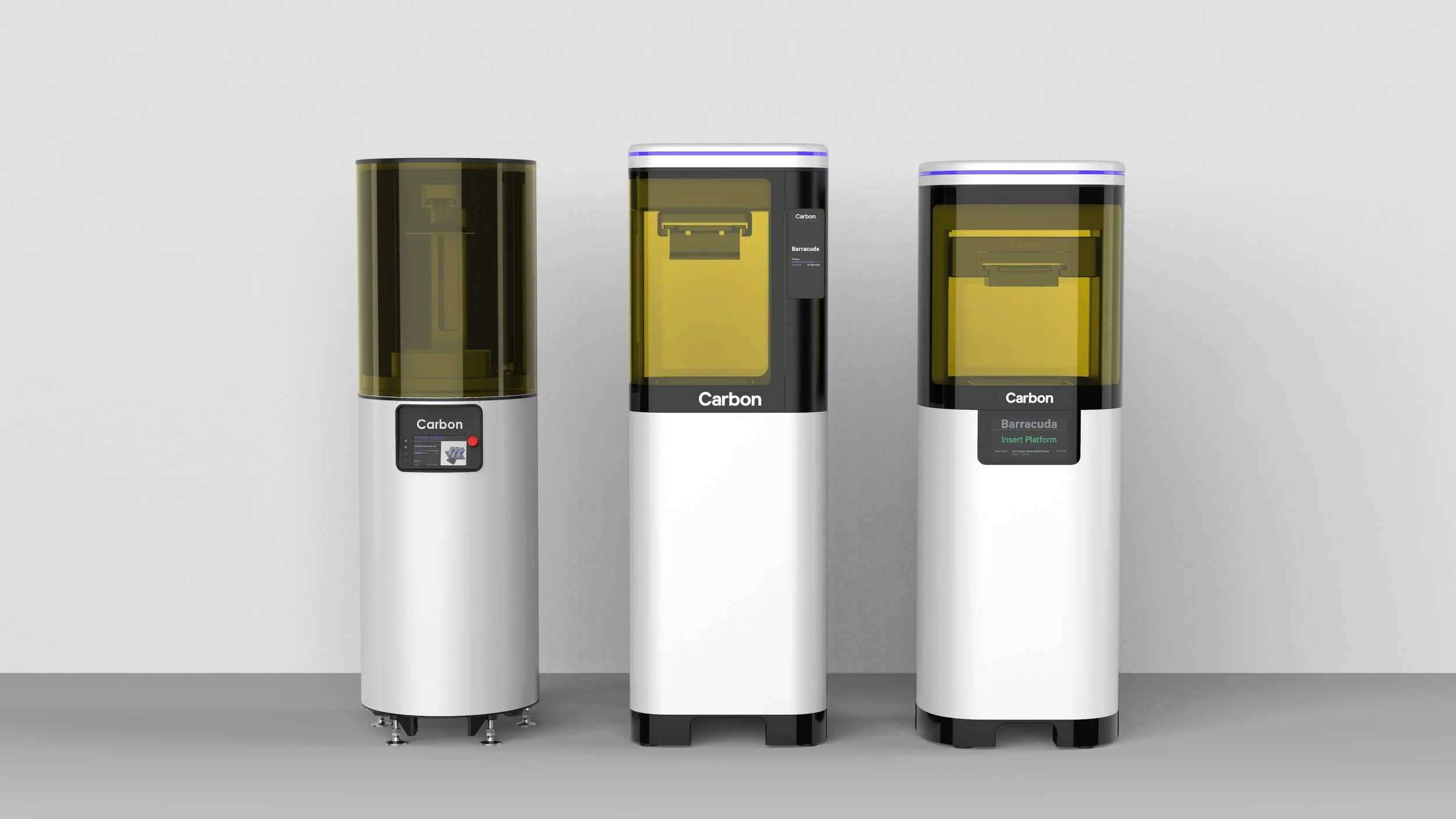

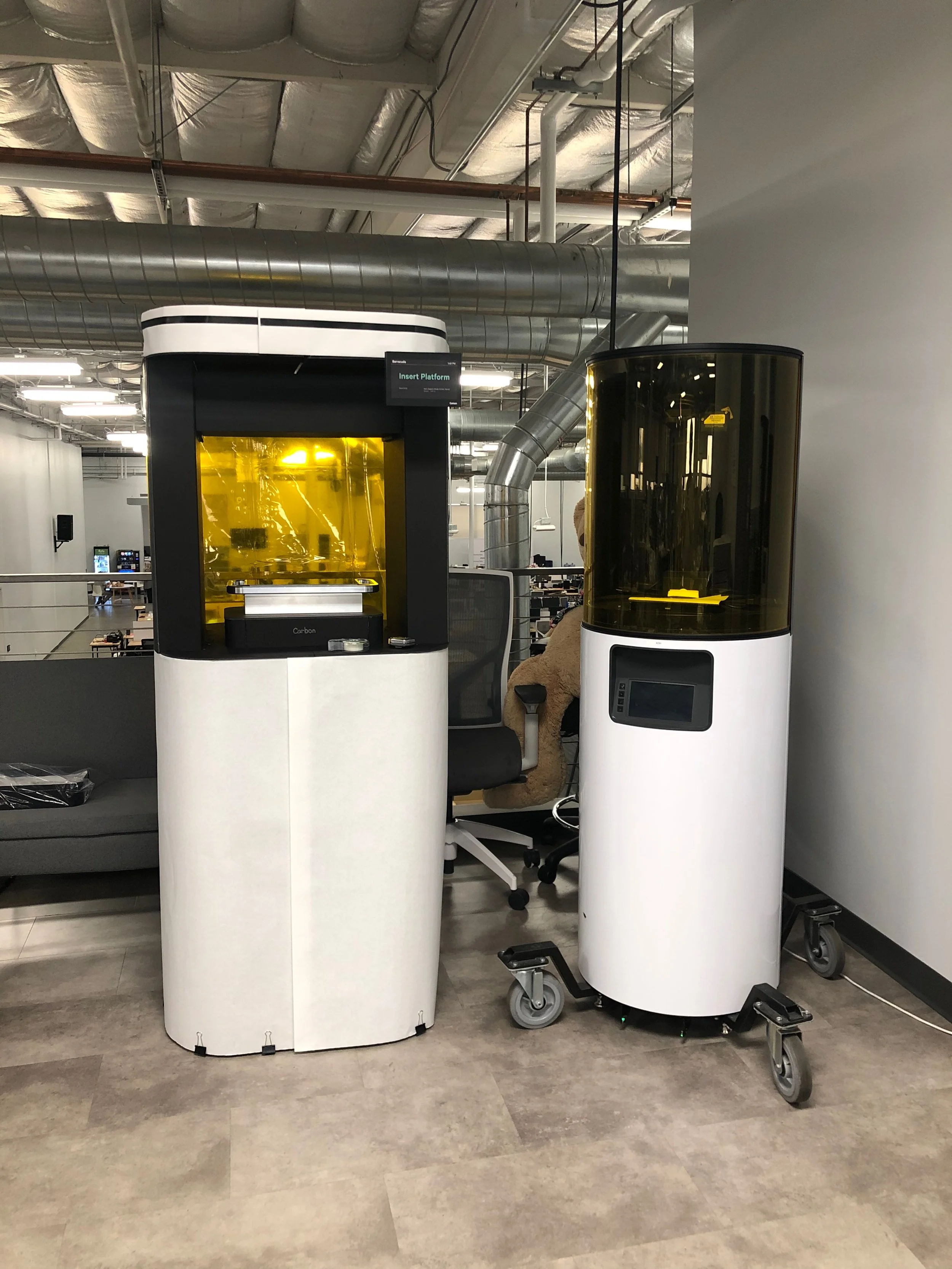

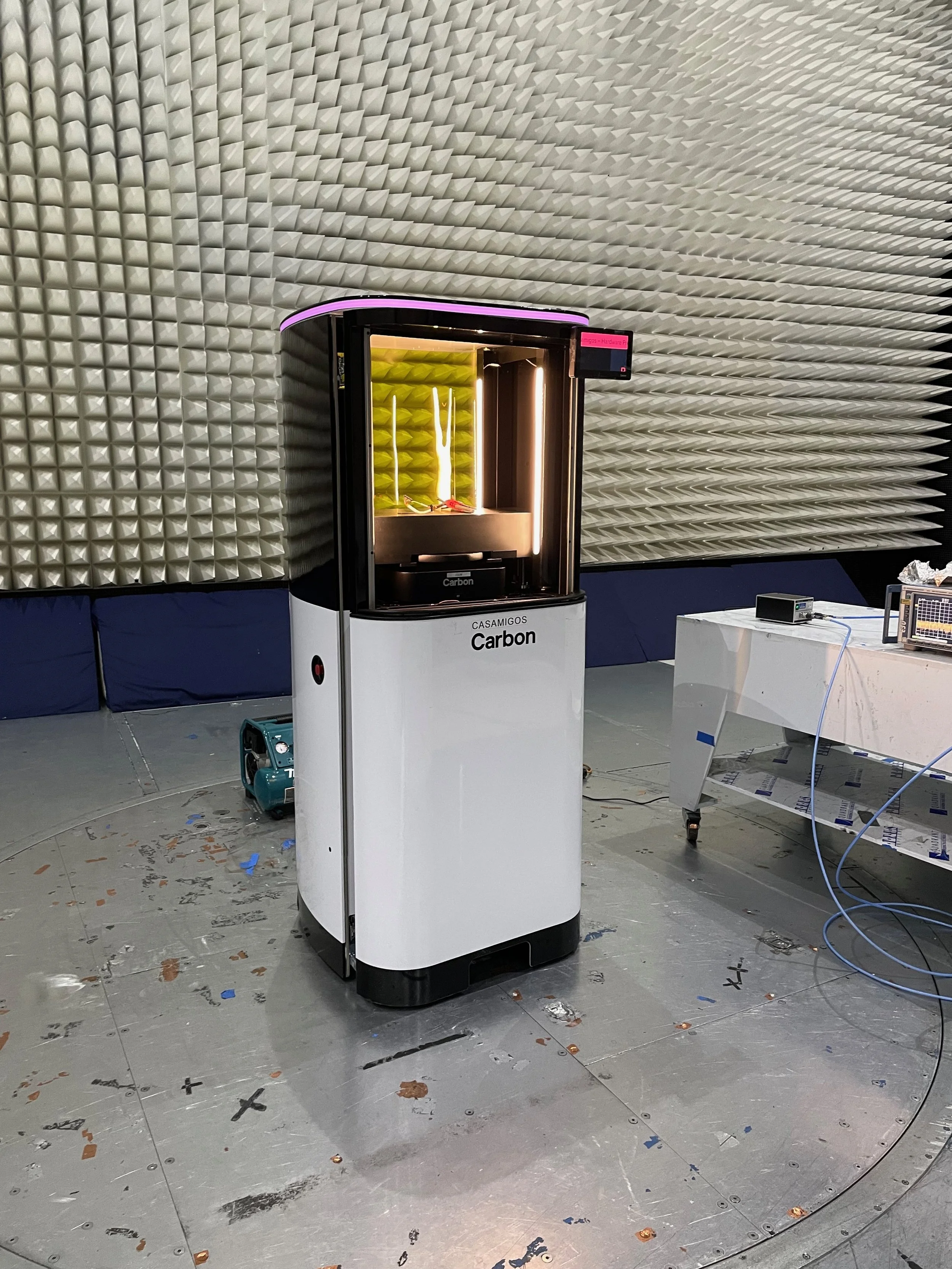

Complete redesign of Carbon’s flagship printer to improve print quality/efficiency, scalability, HMI and alignment with business goals.

Lead the design and development of the Carbon M3 series printers, a high-impact, large-scale redesign with significant visibility across the organization. This project presented unique challenges, requiring solutions adaptable for diverse users, from small studio labs to high-volume manufacturing facilities.

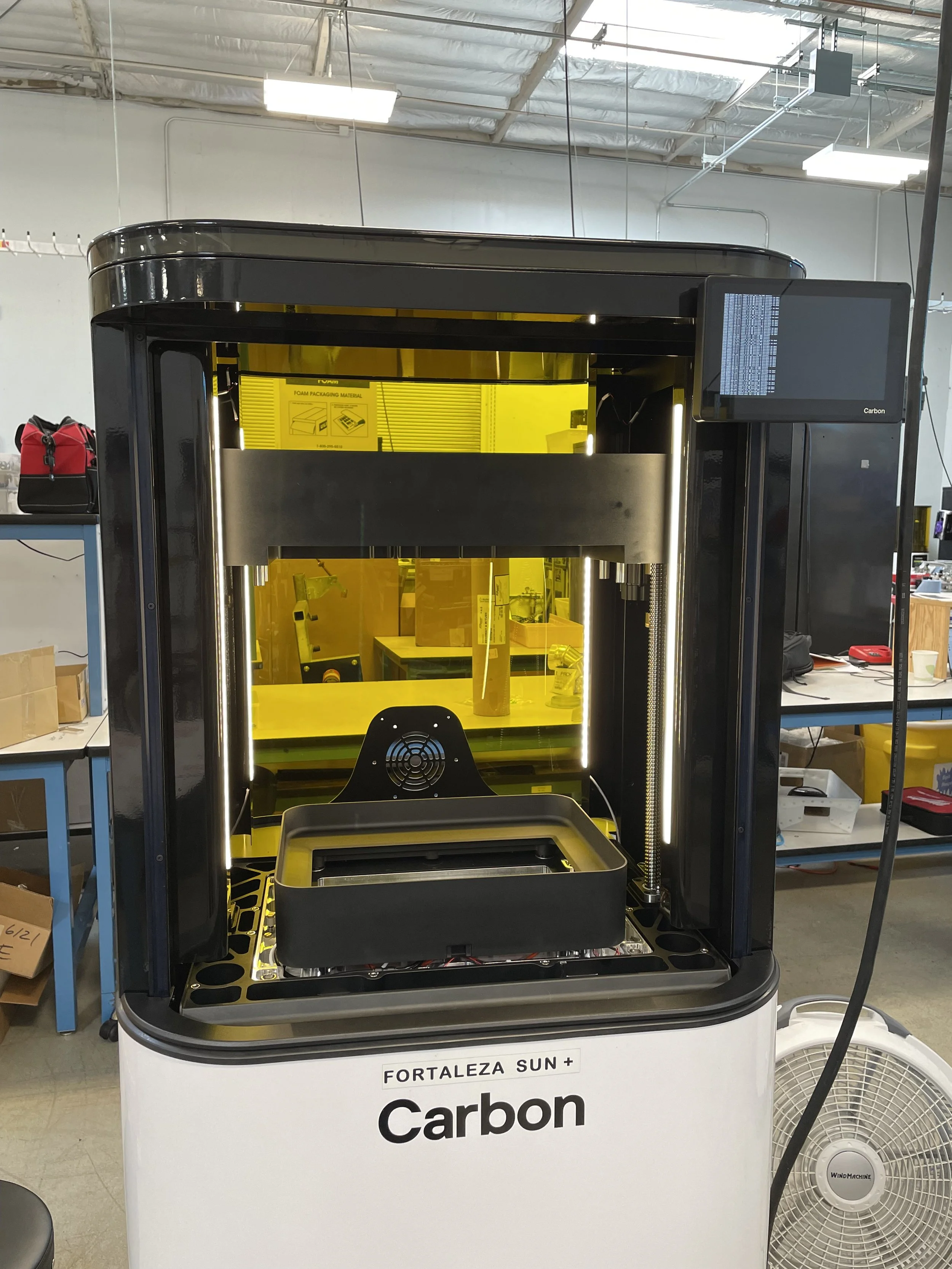

In addition, the design had to accommodate the varying hardware configurations of the M3 and M3 Max within a shared chassis, including the M3 Max's double-sized print area and light engine. This required extensive cross-functional collaboration and strategic foresight.

Faster: Up to 2.5x Higher Throughput

Simpler: Built with You in Mind

Smarter: A Broader Design Space

Smoother: Consistency with a Fine Finish

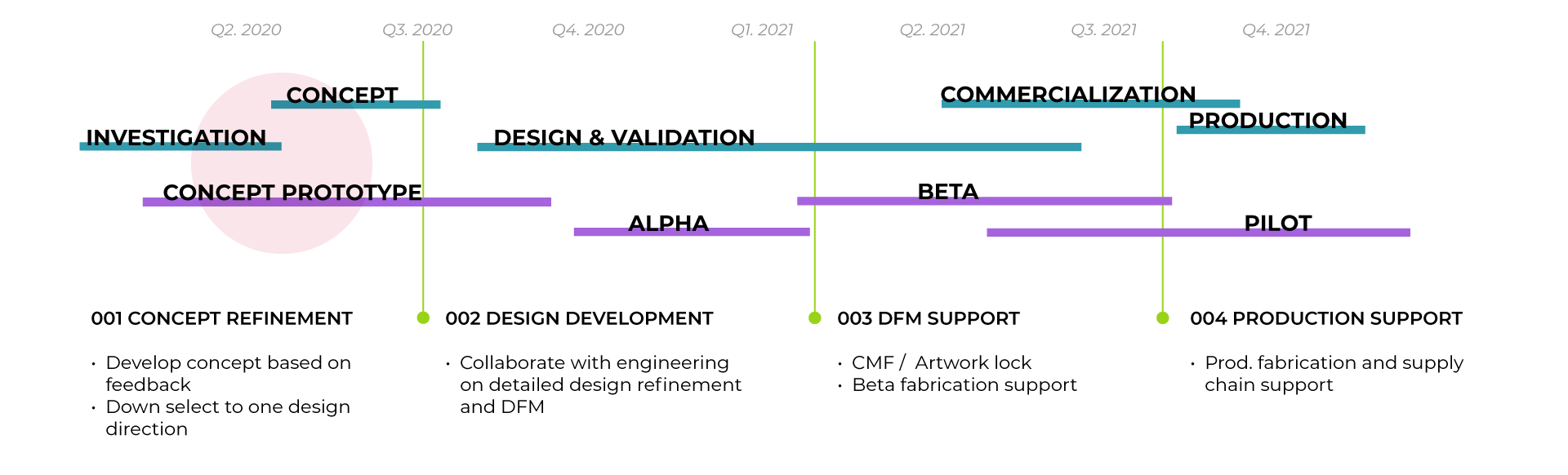

001- INVESTIGATION Challenges

Data compiled from 6 yrs of customer data.

Small (DLP) light engine = small printable area

Cantilever print drive system = slow print time

Not scalable for automation

The cylindrical form factor- “It’s a tube”

Hard to access service panels

Poor display location and UX

Lack of status indication

Many (Overly) complex custom solutions

Poor facilities requirements

001- INVESTIGATION Product Requirements

Print performance increase

First print success

Speed & Quality

Increase annual resin sales

BOM cost reduction (always…)

Scalability for automation and lights out production

Single chassis design for 2 DLS engine sizes

Hardware serviceability and cleanability

Ease of install- HW and SW

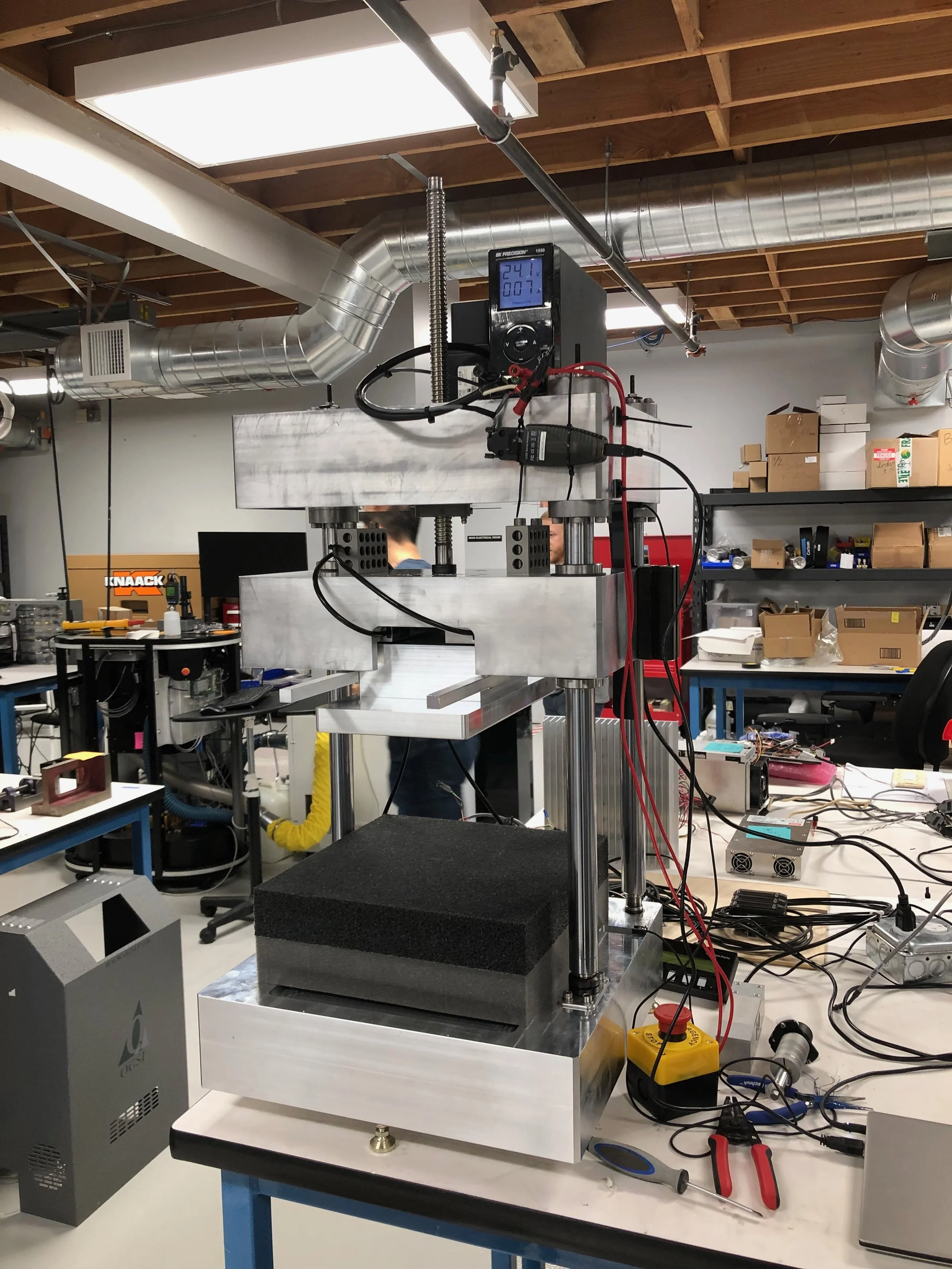

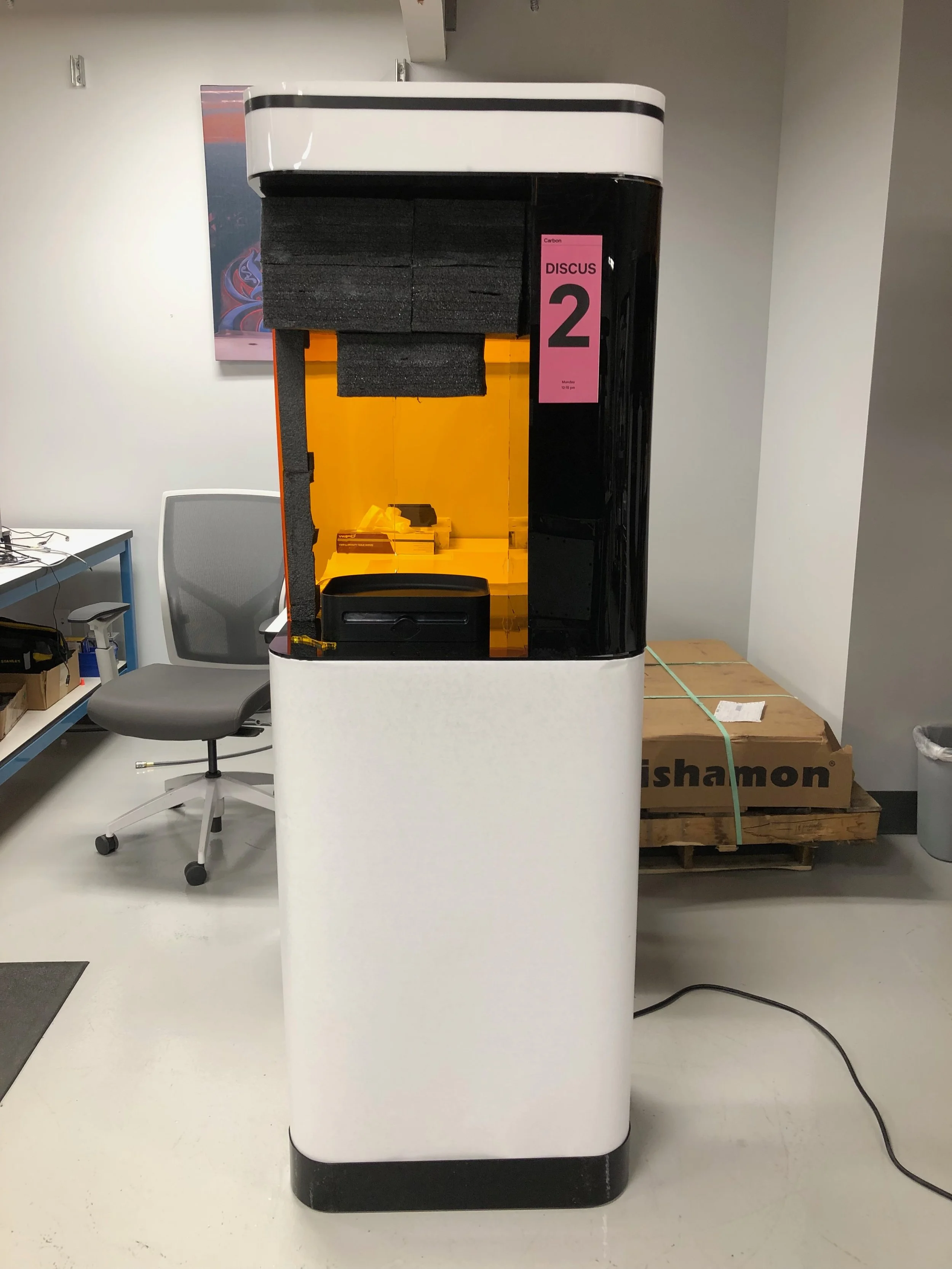

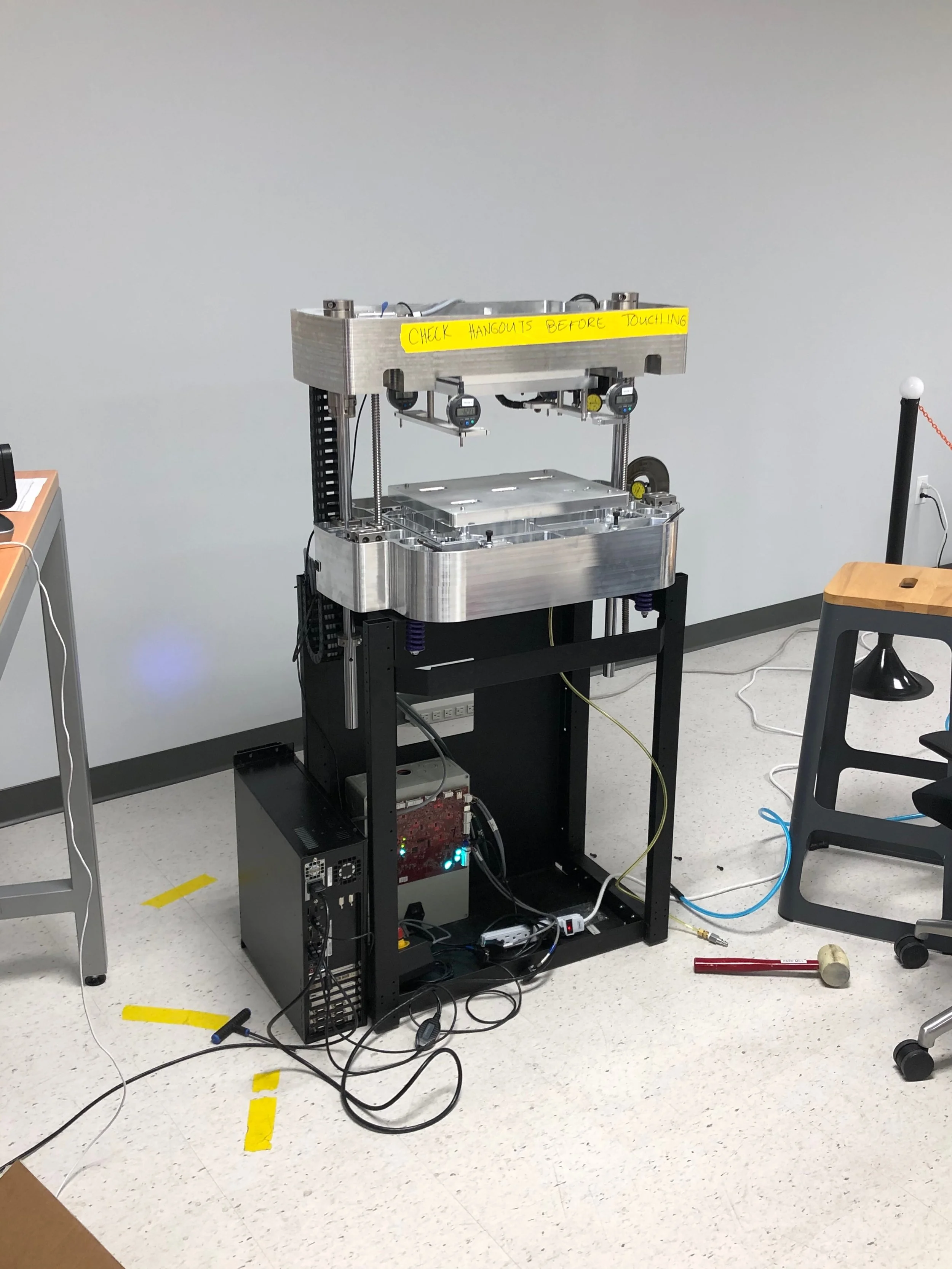

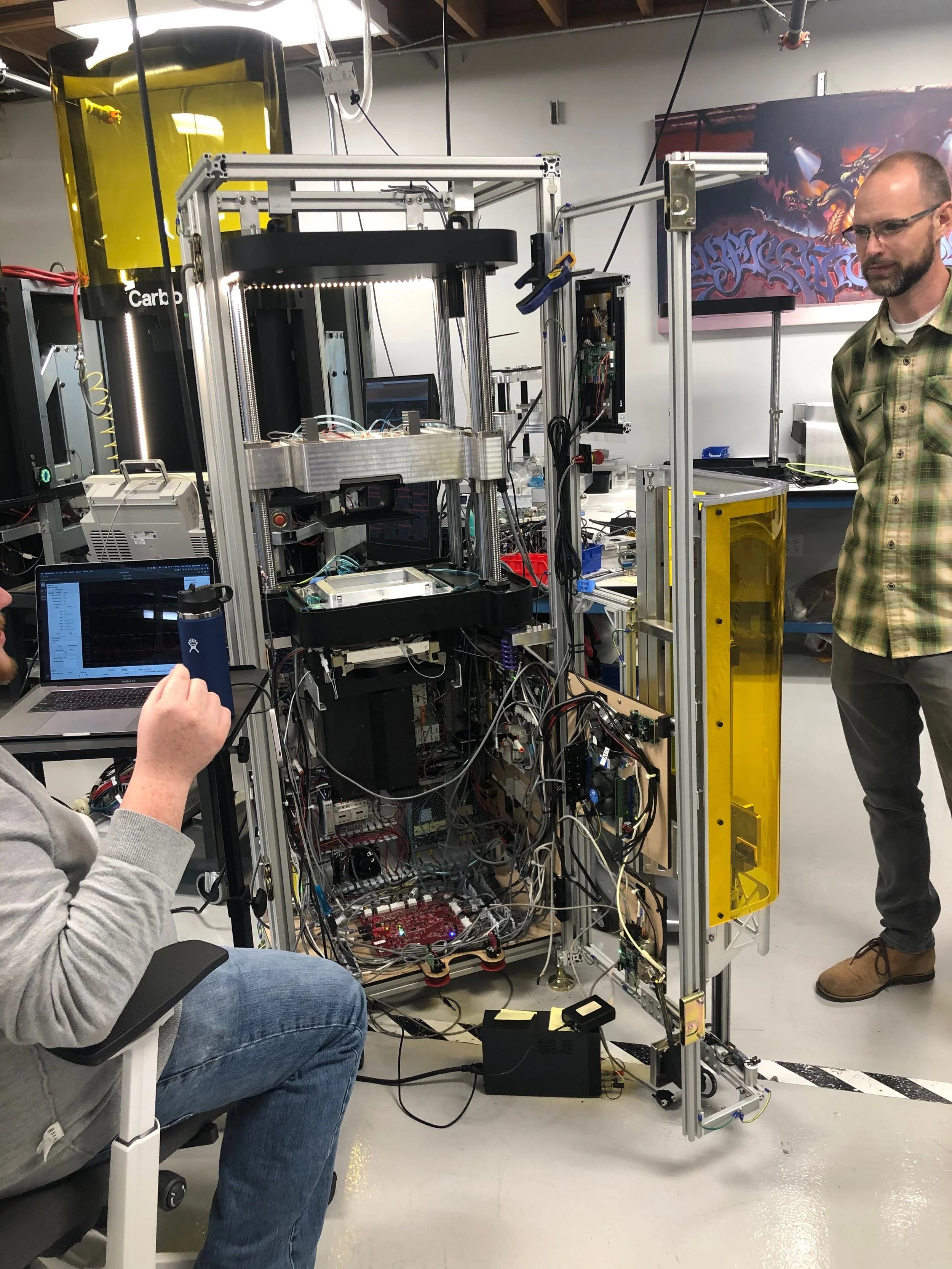

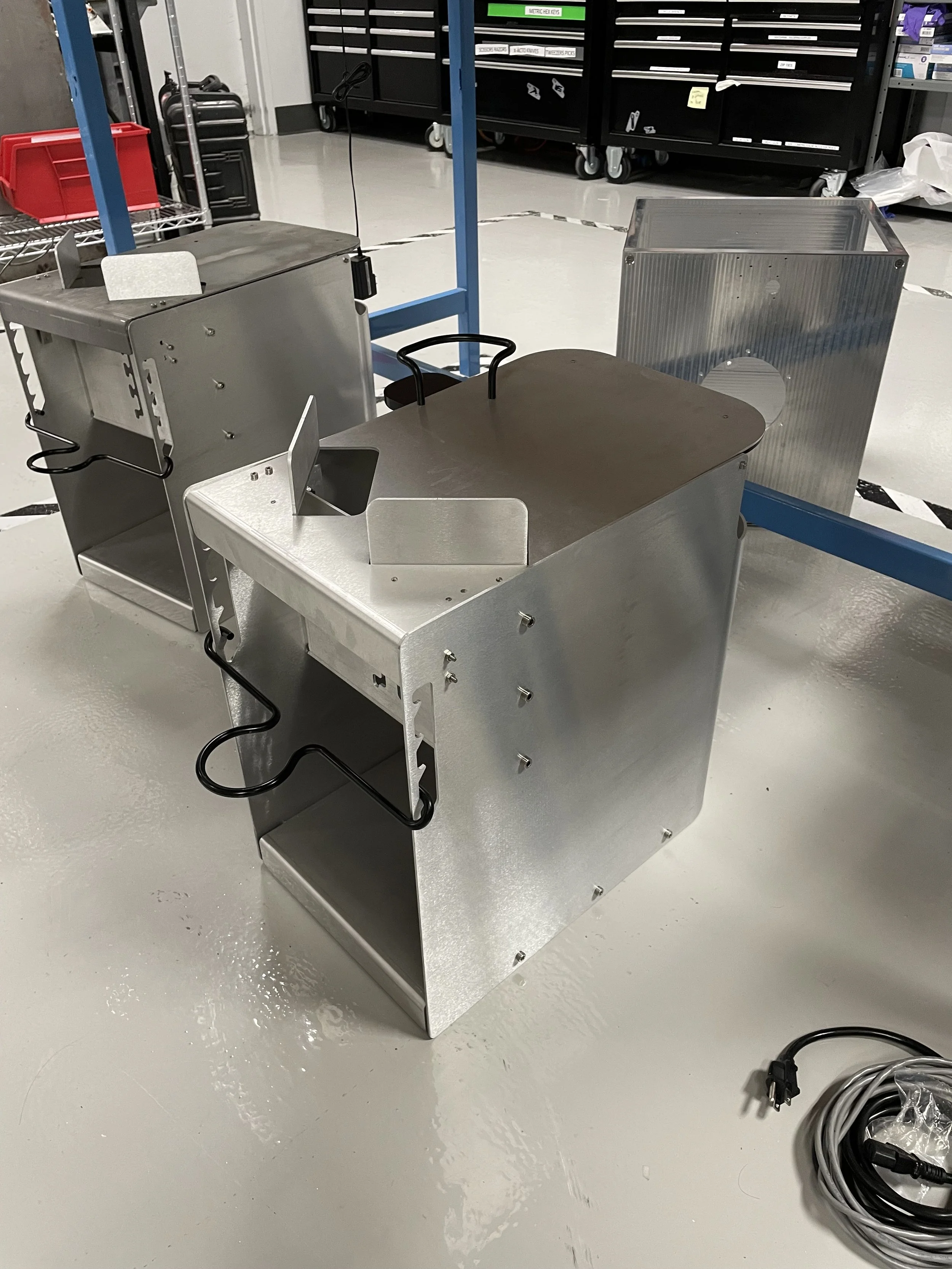

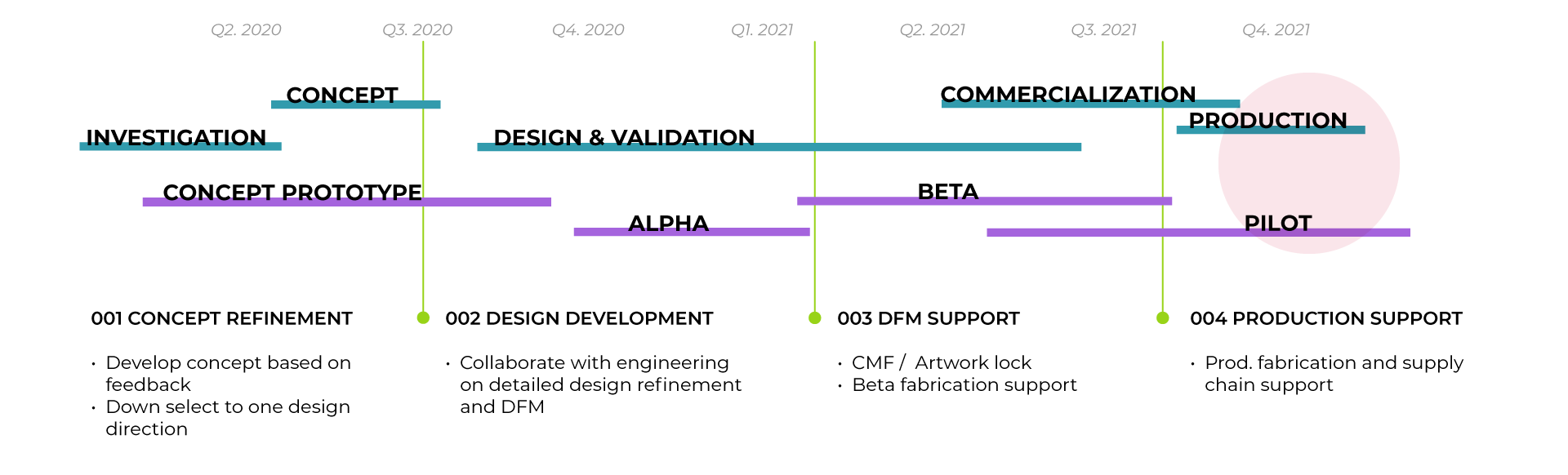

001- CONCEPT PROTOTYPE

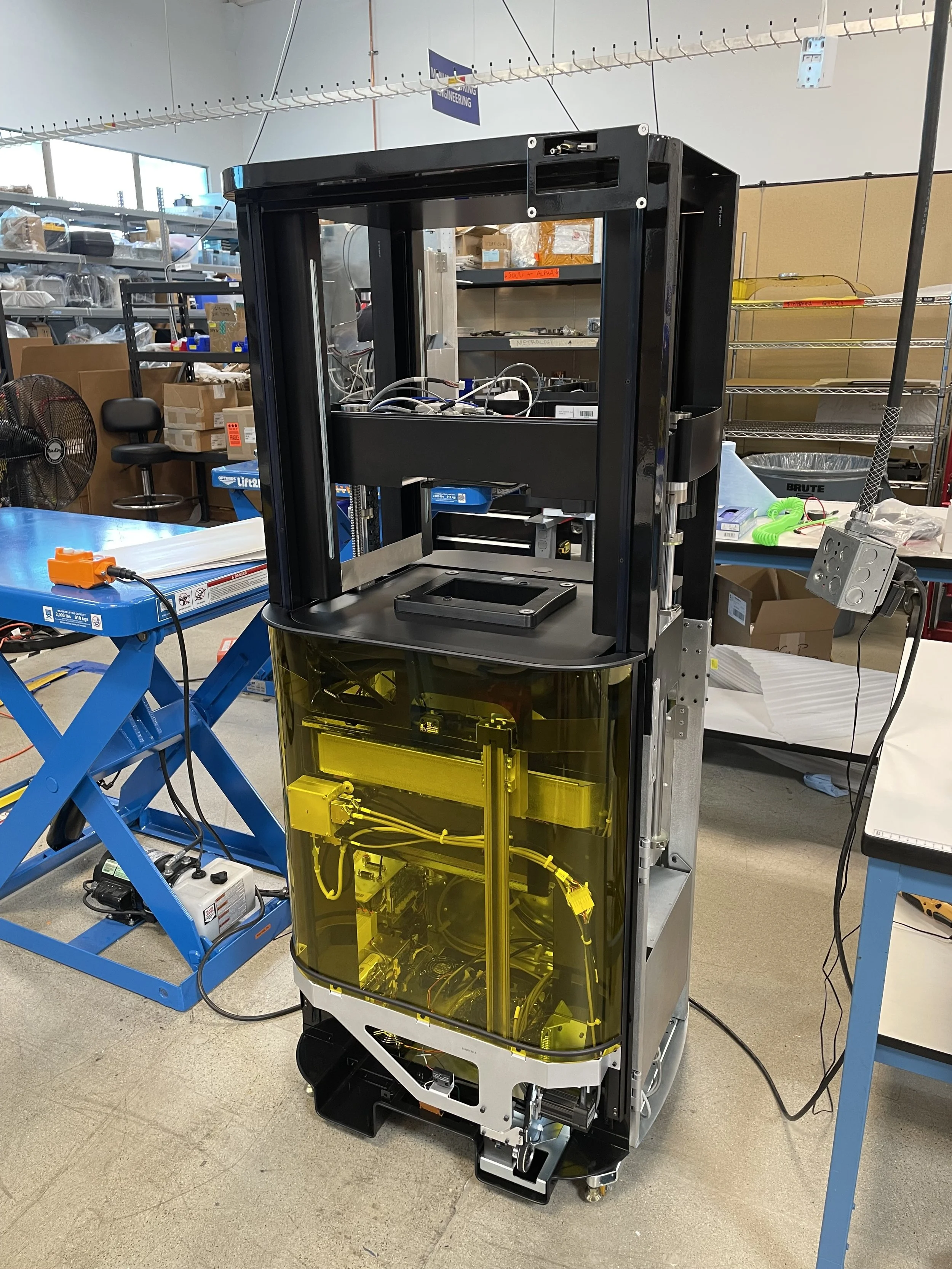

Engineering R&D: Z-Drive System Designs and Comparison

Single motor (center) drive system v.s. Dual motor (sym. and asym.) drive system, all developed as R&D units.

Print drive efficiency analysis + FEA

Initial BOM cost study (business case)

001- DESIGN SPACE EXPLORATION

Initial ID Concepts

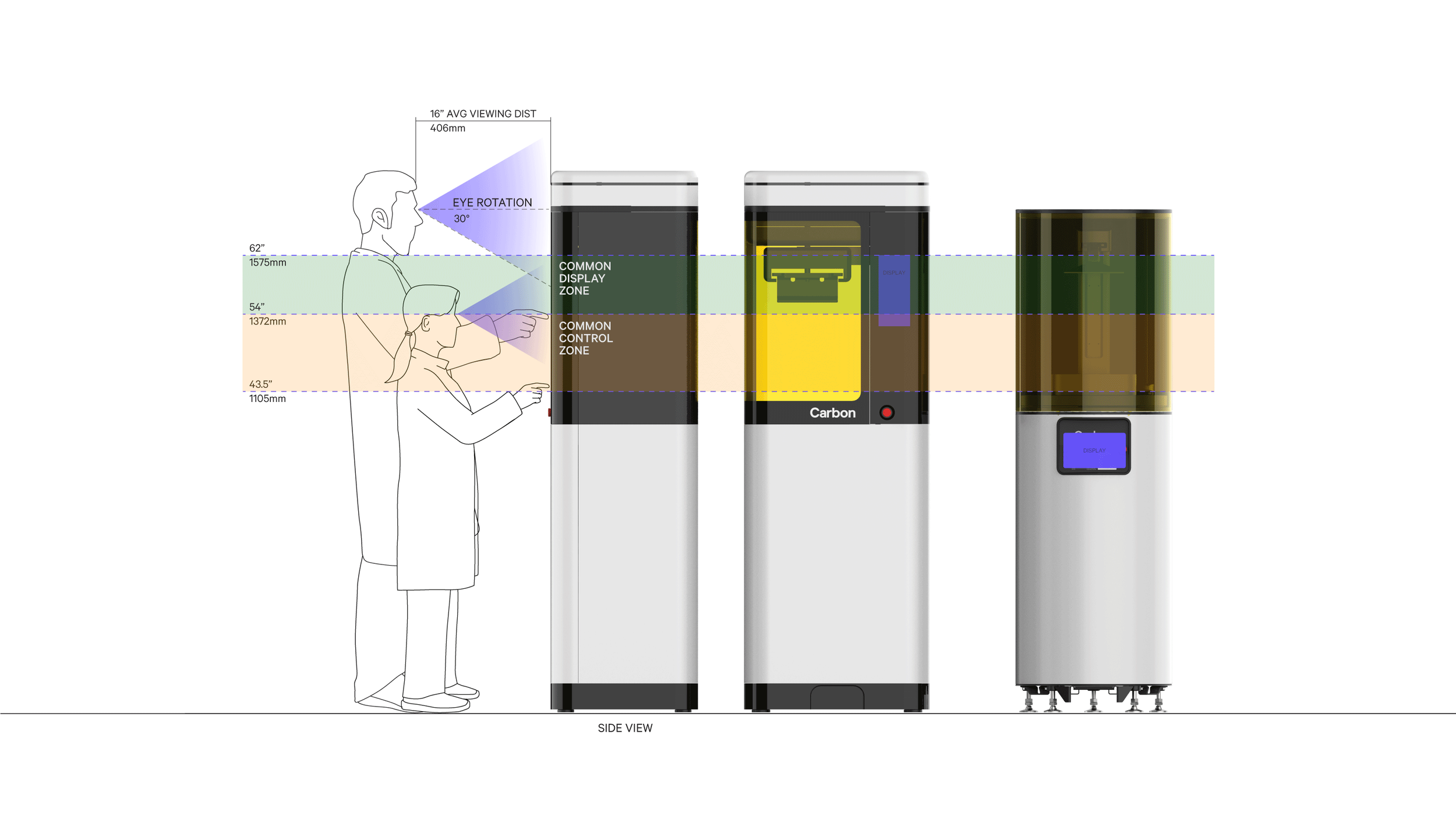

On/Off-site UX & Ergonomics research and testing (customer sites) on developing concepts.

UX on user journey

Facilities requirement documentation

ADA and interior design requirements

Specific customer requirements- eg. J&J

Serviceability and accessibility

001- Key Learnings Decision Drivers

Customers wanted higher yield with more printable area, faster print speed. Cannot keep up with demand but committing to additional printers is challenging.

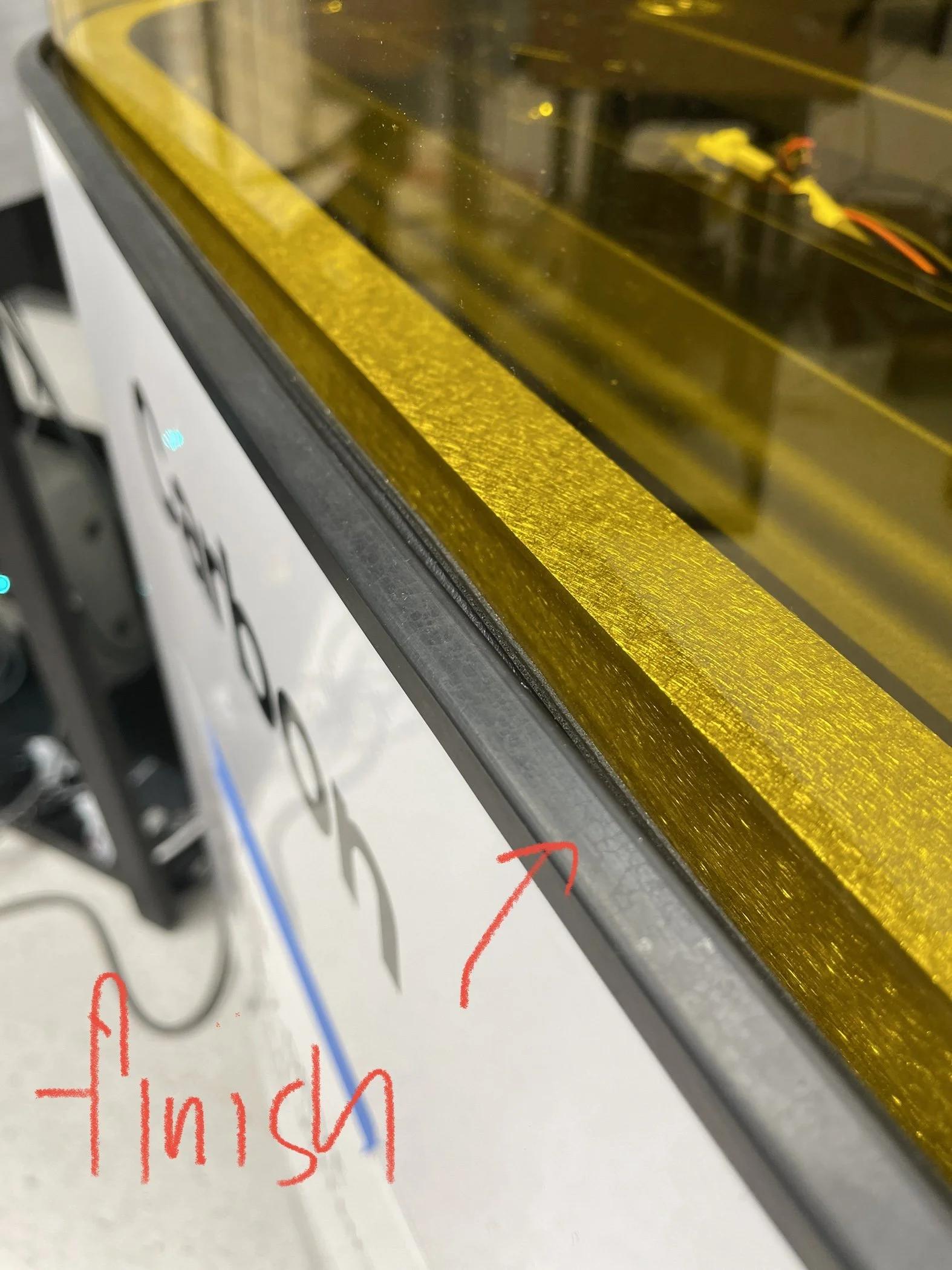

Higher quality prints with less layer lines. This requires less post-processing time.

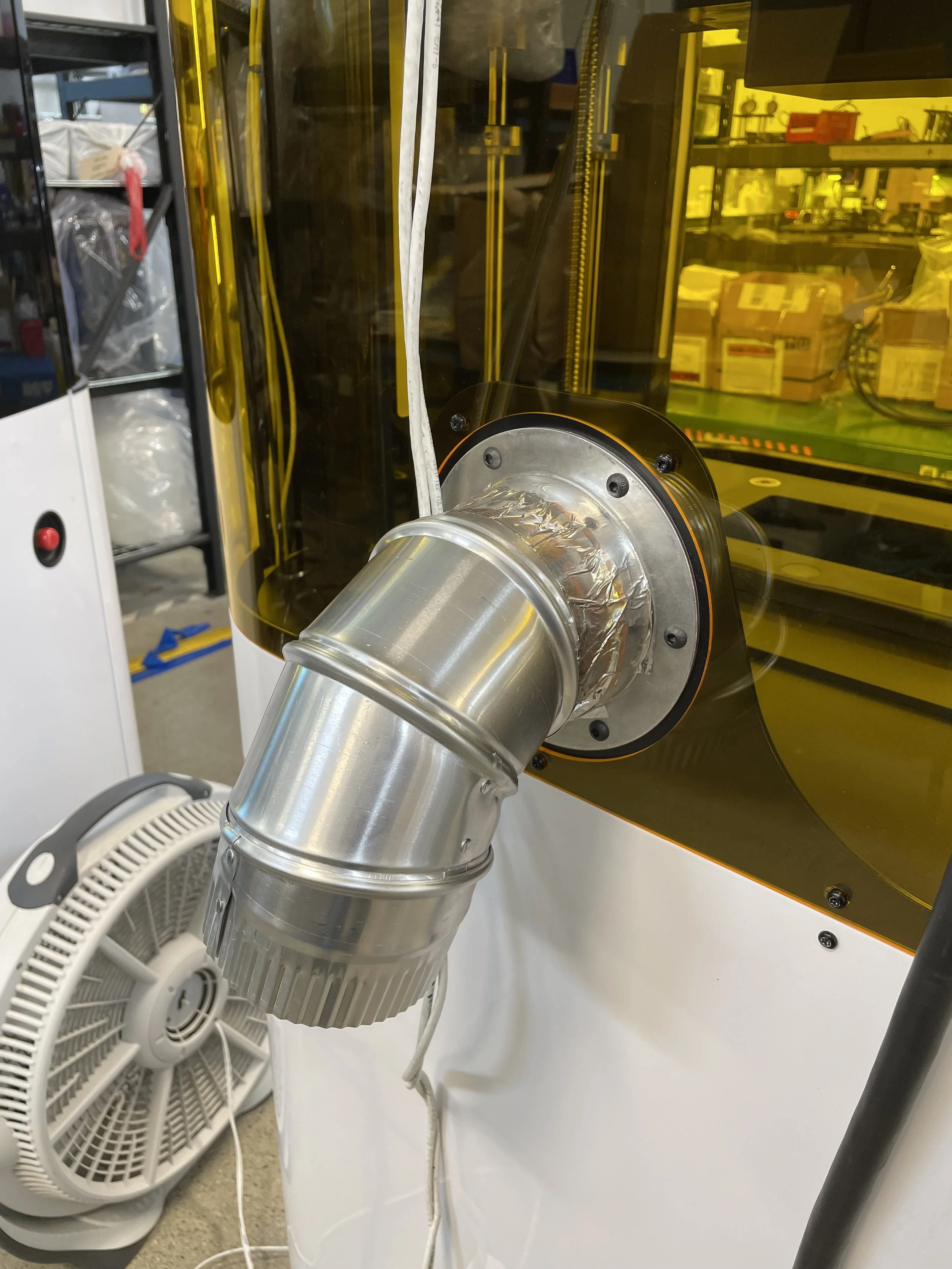

Poor service experience of the light engine and other key components, such as the oxygen sensor and electronics. Currently, on the M2, all side panels must be removed for service, resulting in poor facility requirements.

Print deck accessibility is critical for cassette and platform UX.

Automation requirements- scalability for robots and other automated attachments.

Poor HMI experience with existing printer

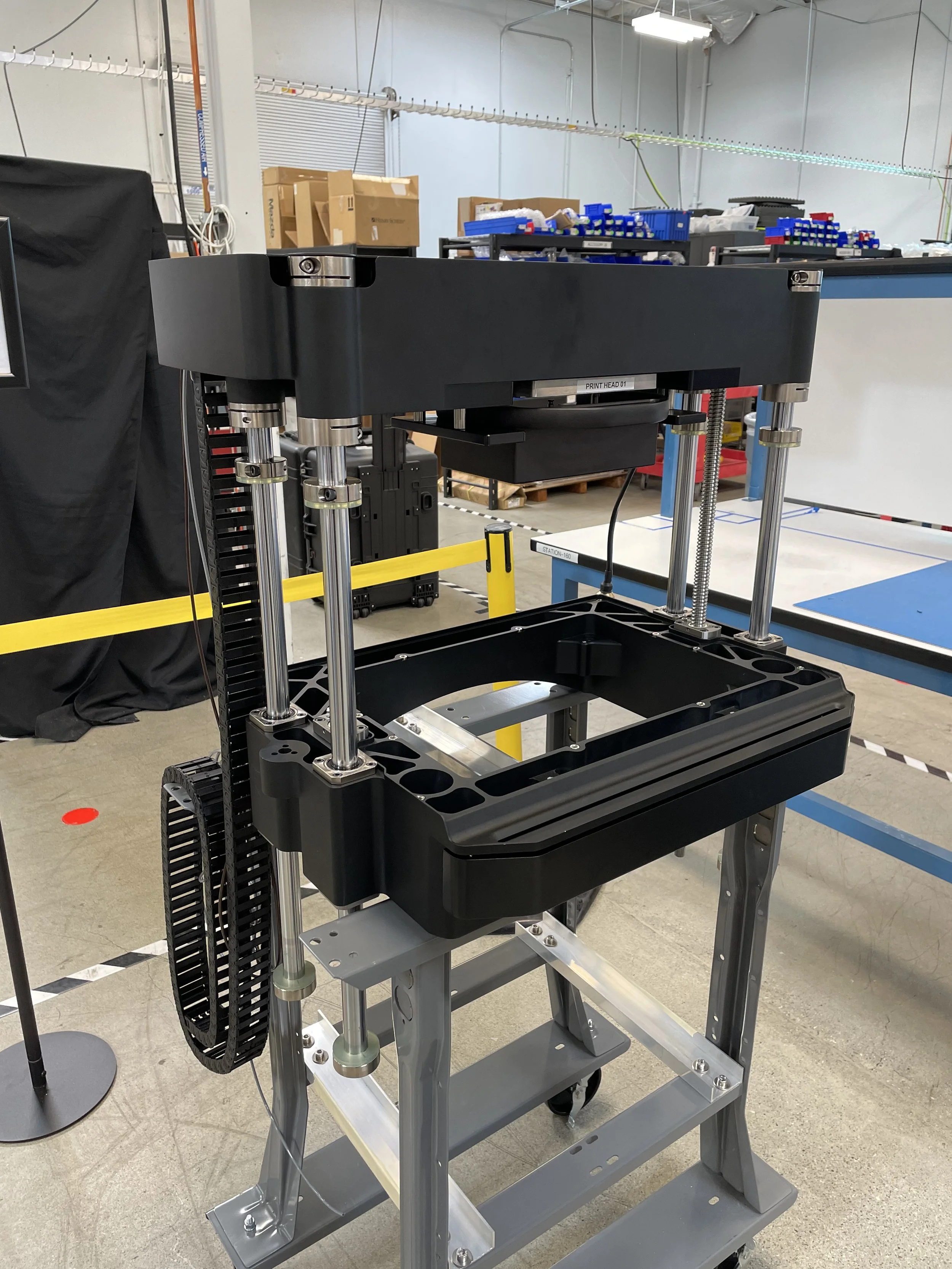

Twin Drive System ->

The more robust and scalable system

Twin drive system allowed parts to print and pump at a higher rate while holding part accuracy

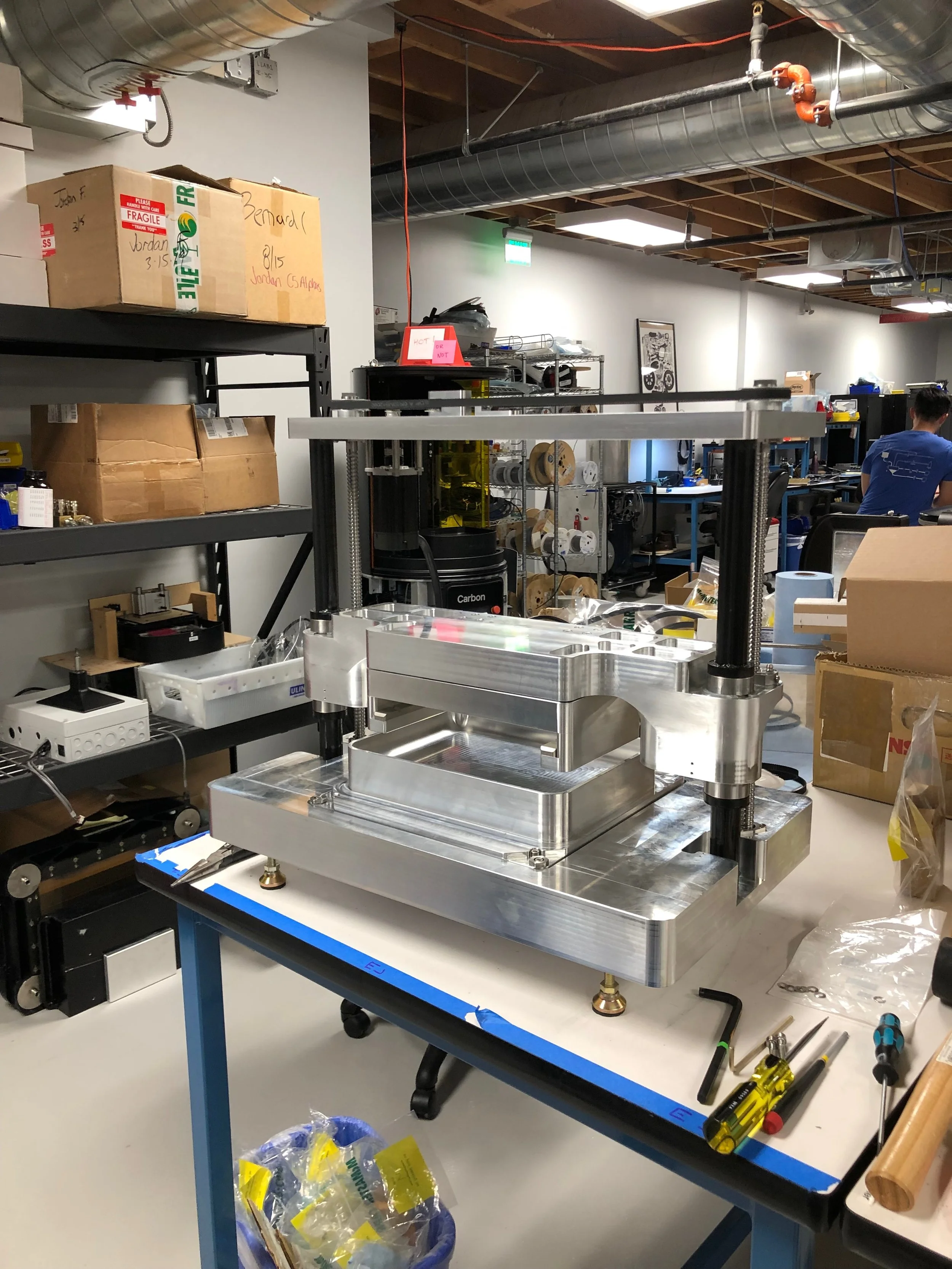

001- CONCEPT REFINEMENT

ME & ID Packaging Design

Finding the right balance between function and aesthetics while staying true to the Carbon brand identity

Single chassis design

Service and Facility requirements

Printer ergonomics and UX

Carefully work through touchpoints like Display, Cassette and Platform UX

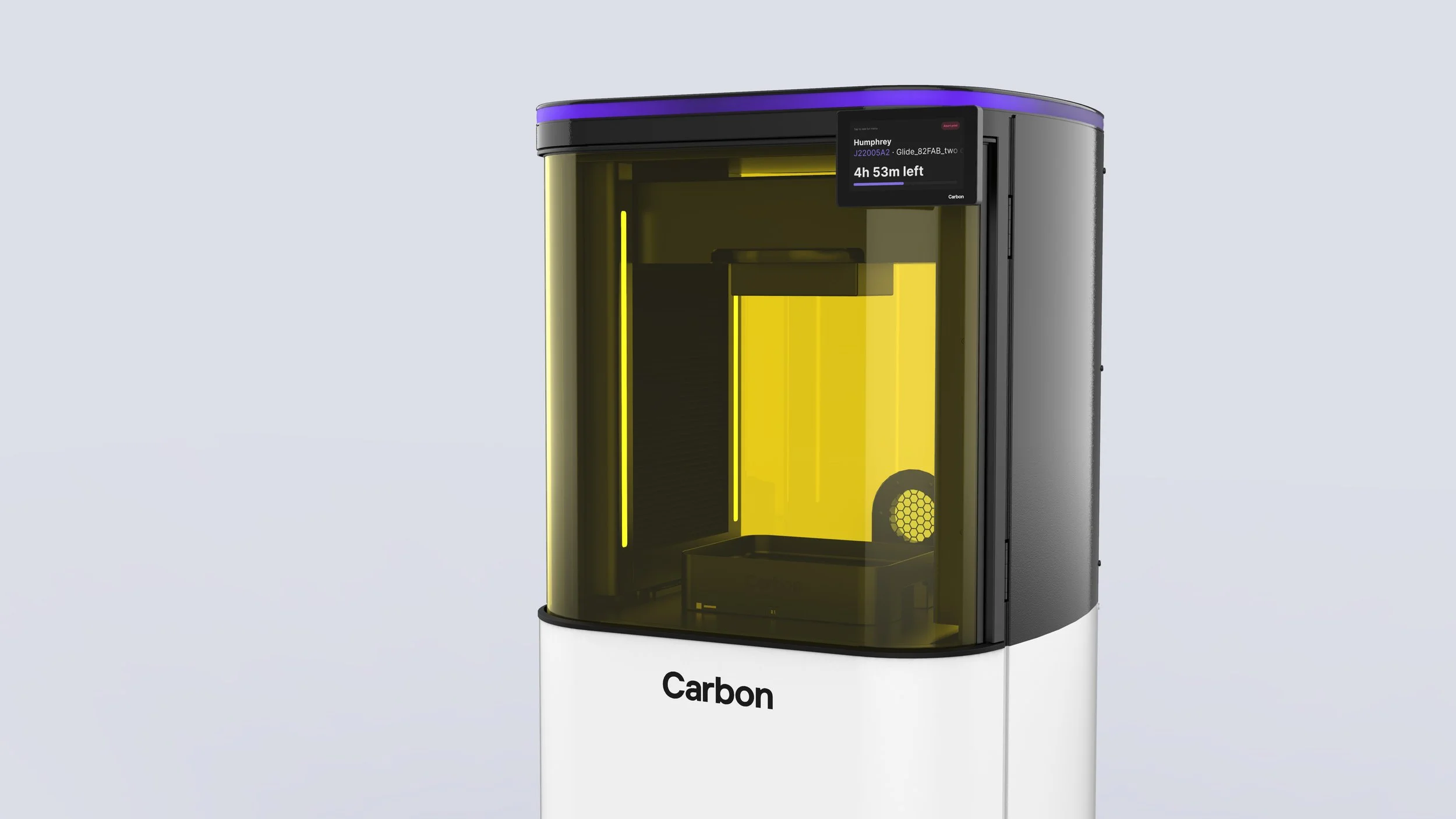

HMI Design

Custom Touchscreen display

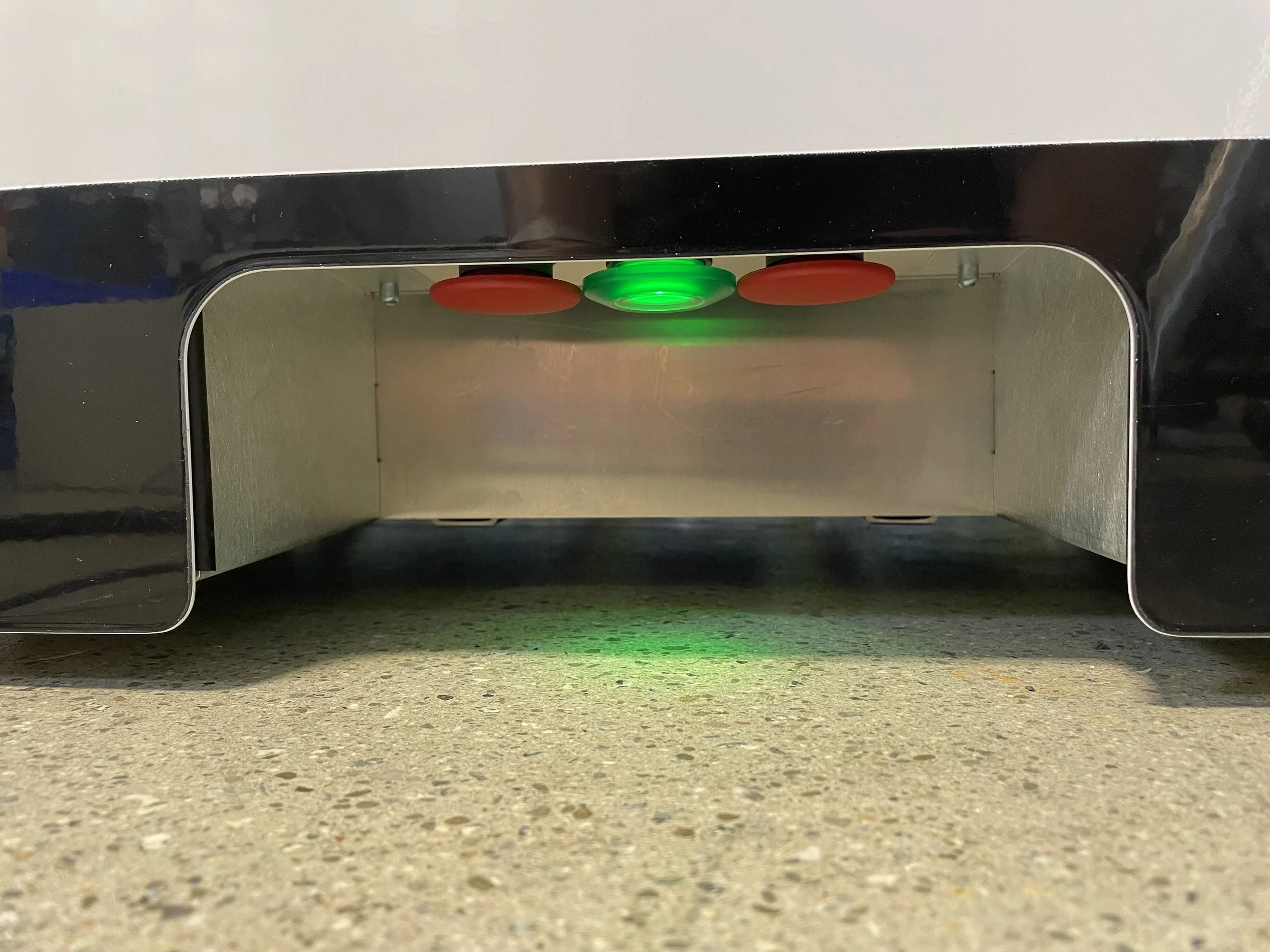

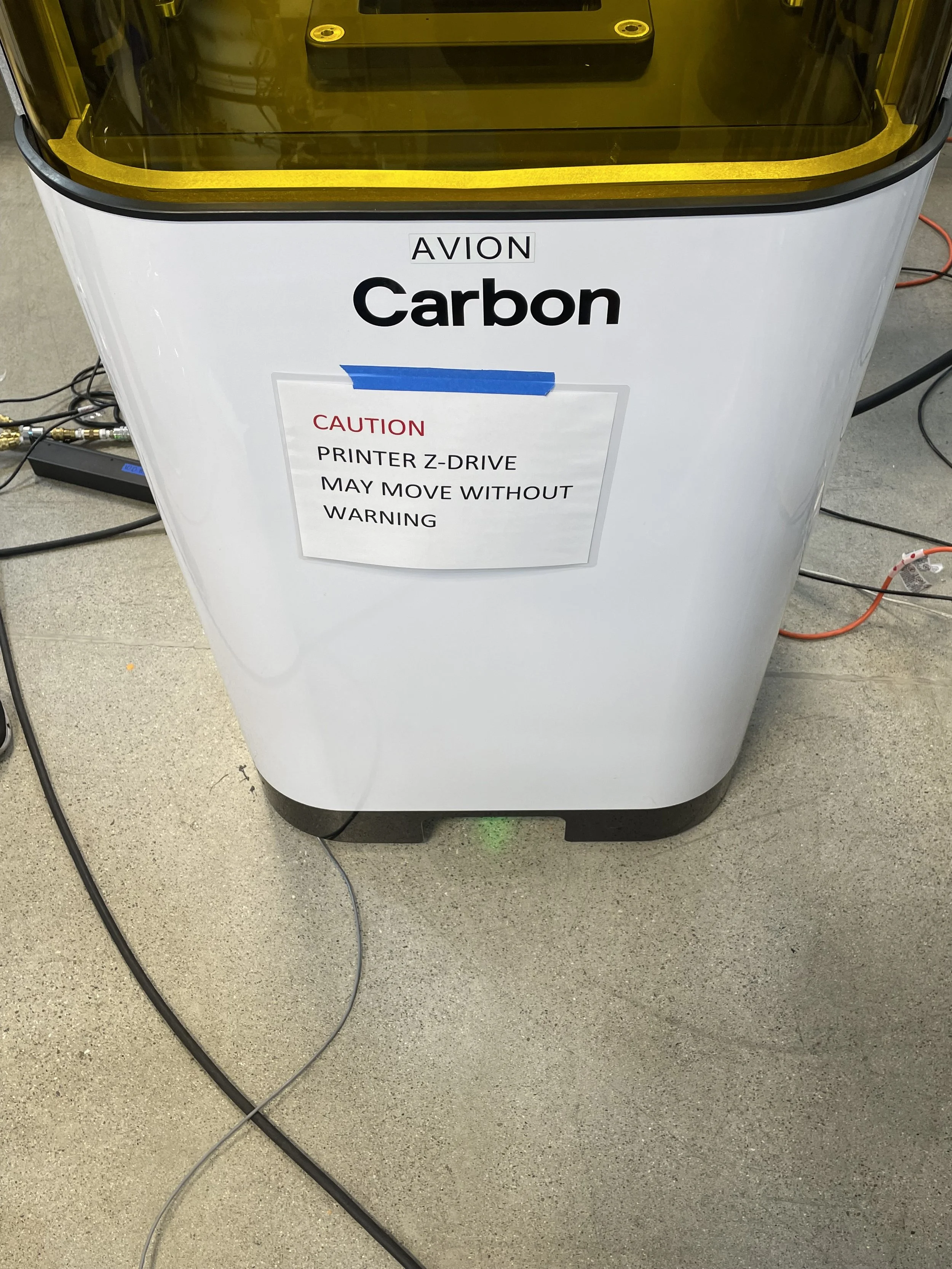

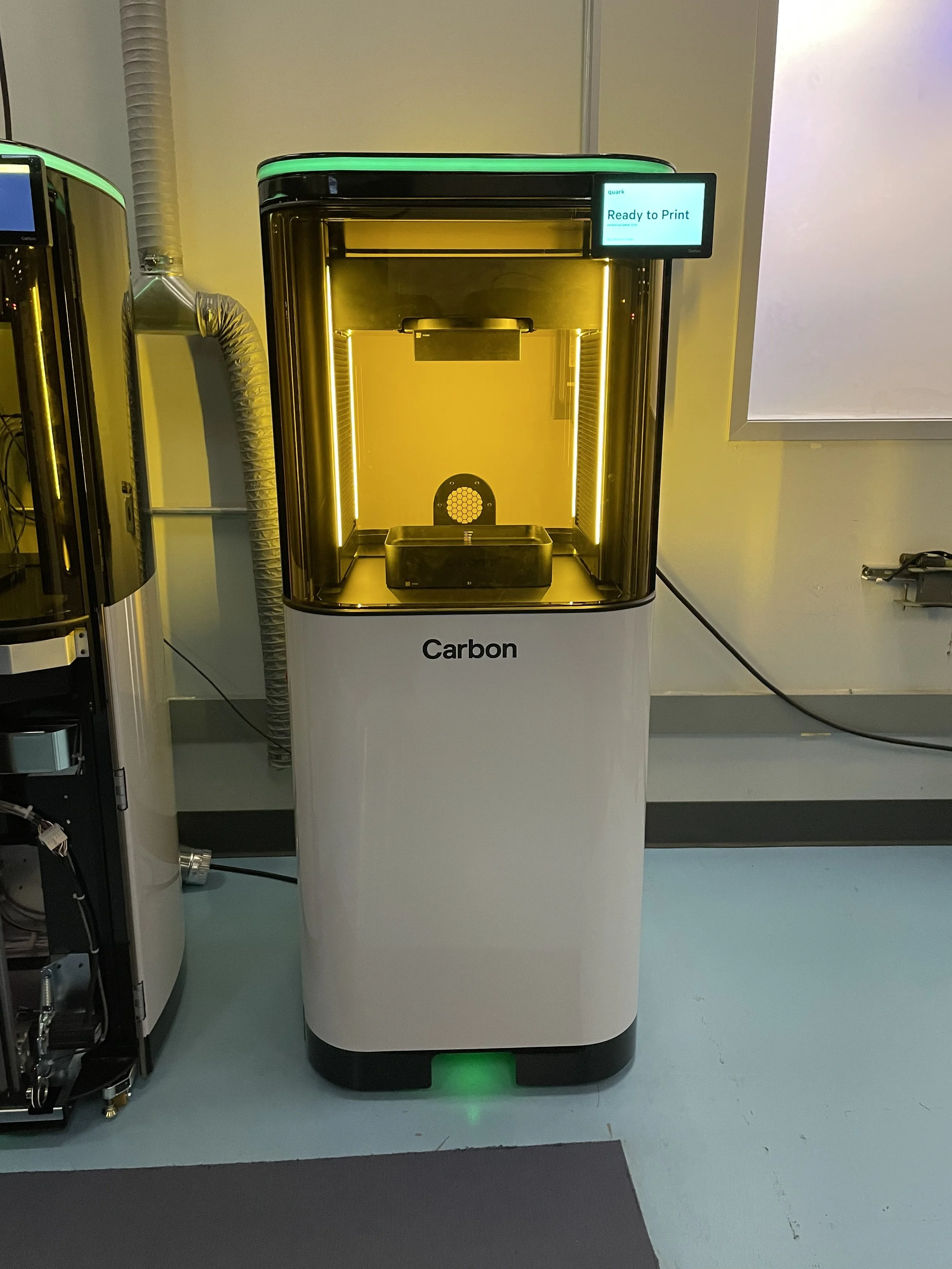

Visual status indication through an integrated LED status bar on top of device as well as interior lighting

Audible feedback

Mechanical v.s. digital switches

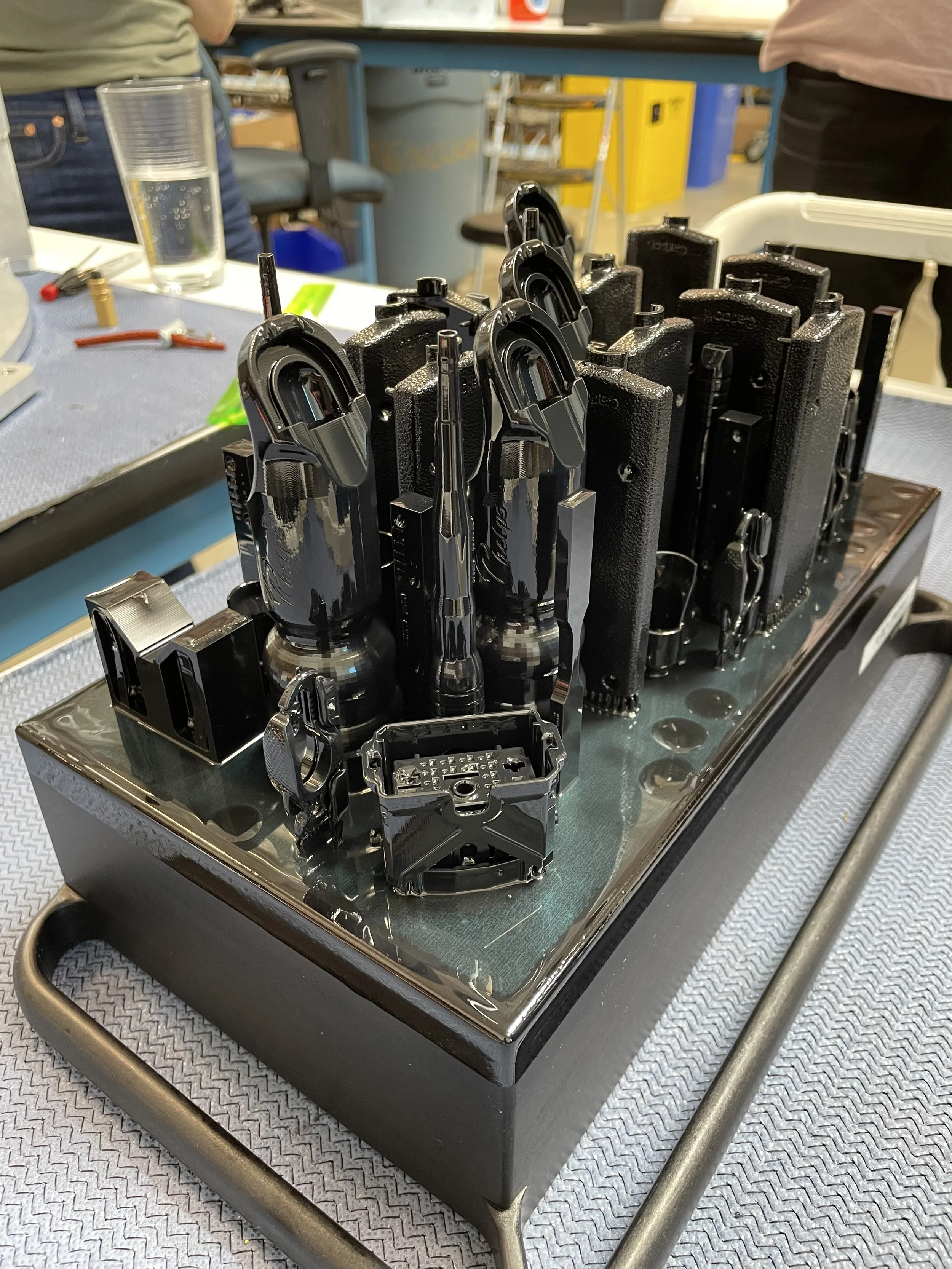

002 DESIGN DEVELOPMENT

Lead the design and development of all ID and HMI features. Working cross-functionally with ME, EE, Print Dev. and SW teams.

Print arm, platform and cassette ID

Touch screen

LED status bar

Service access door

Custom notification sound design

Interior lighting

CMF

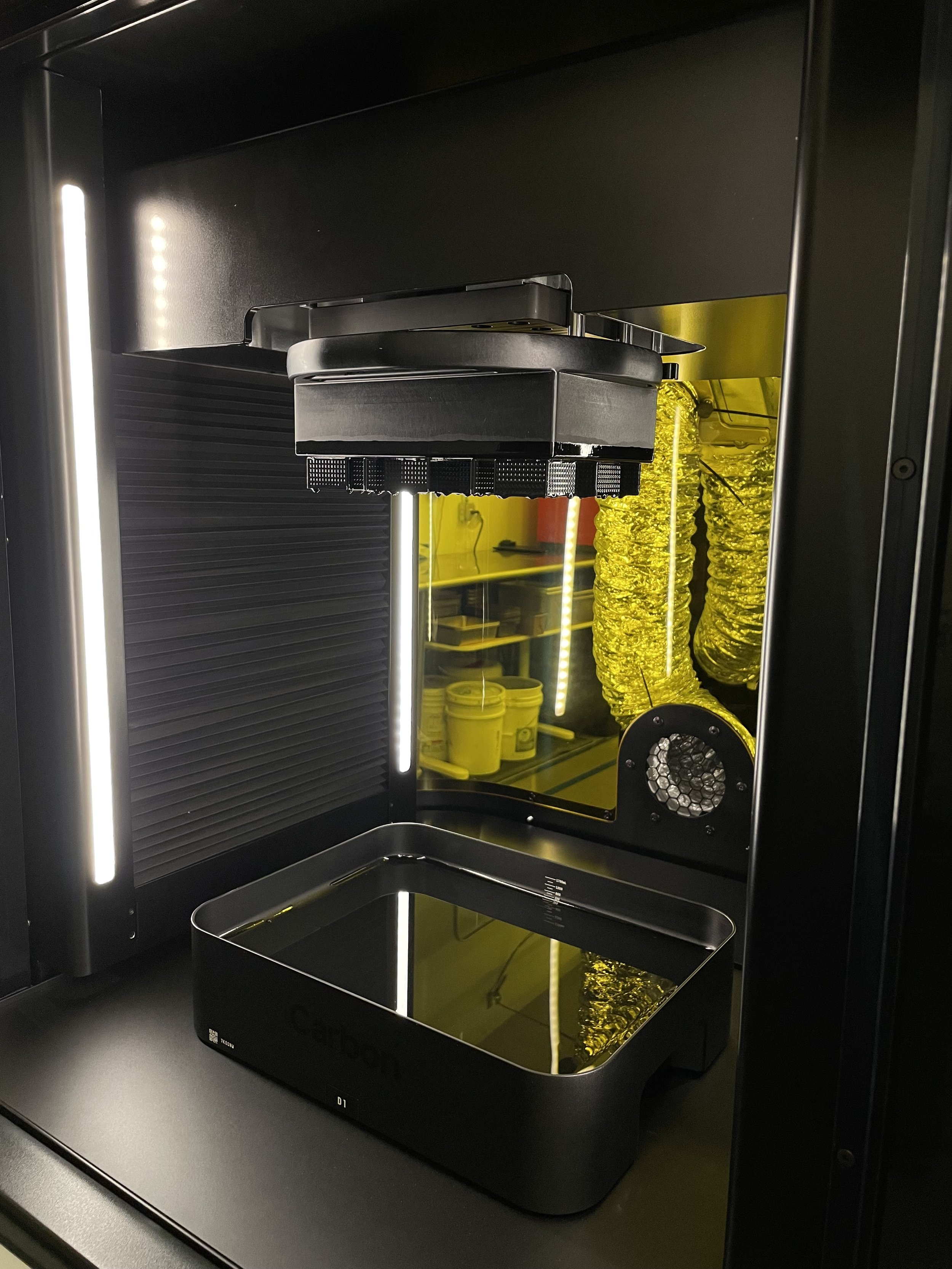

Alpha Builds

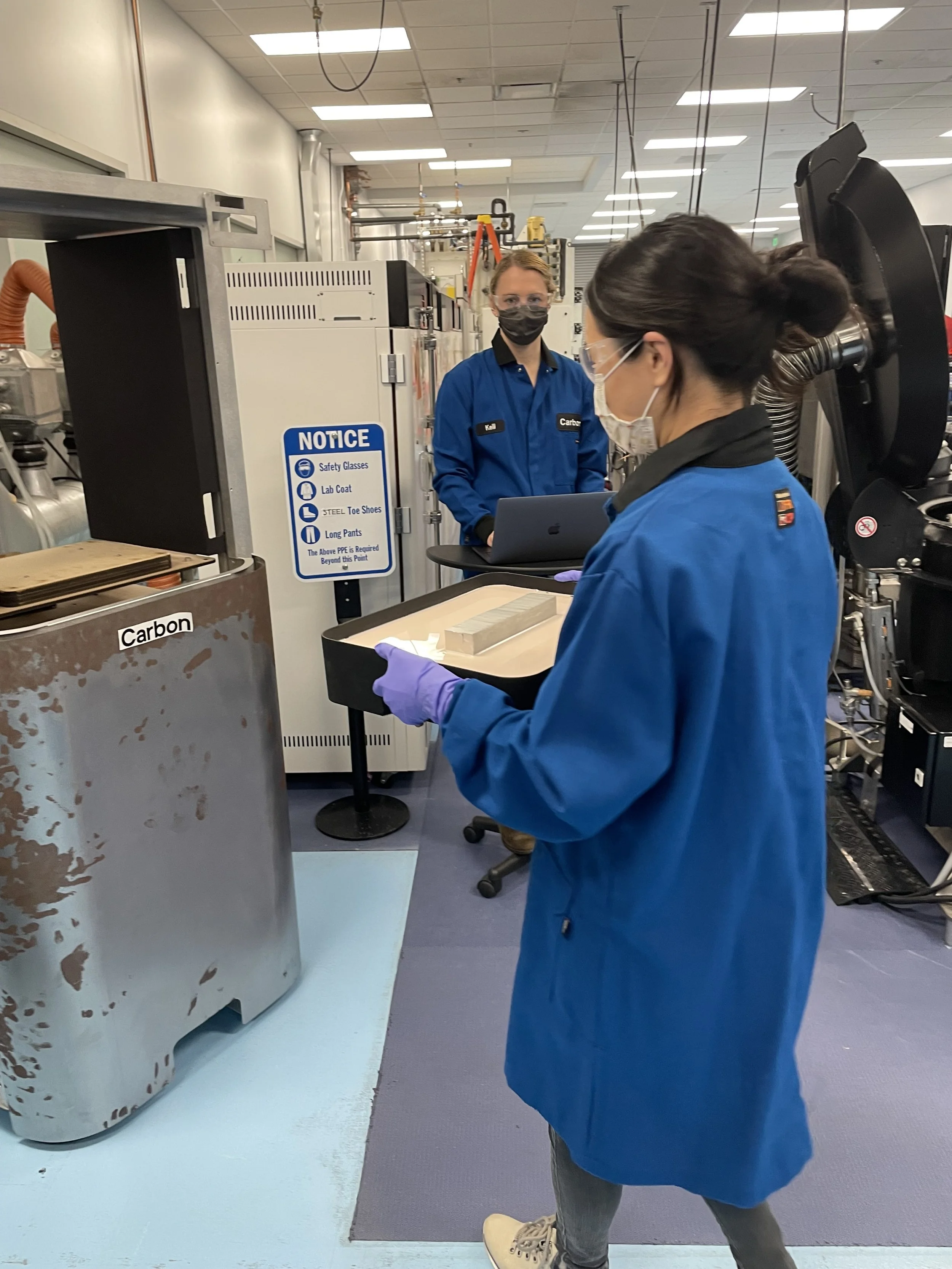

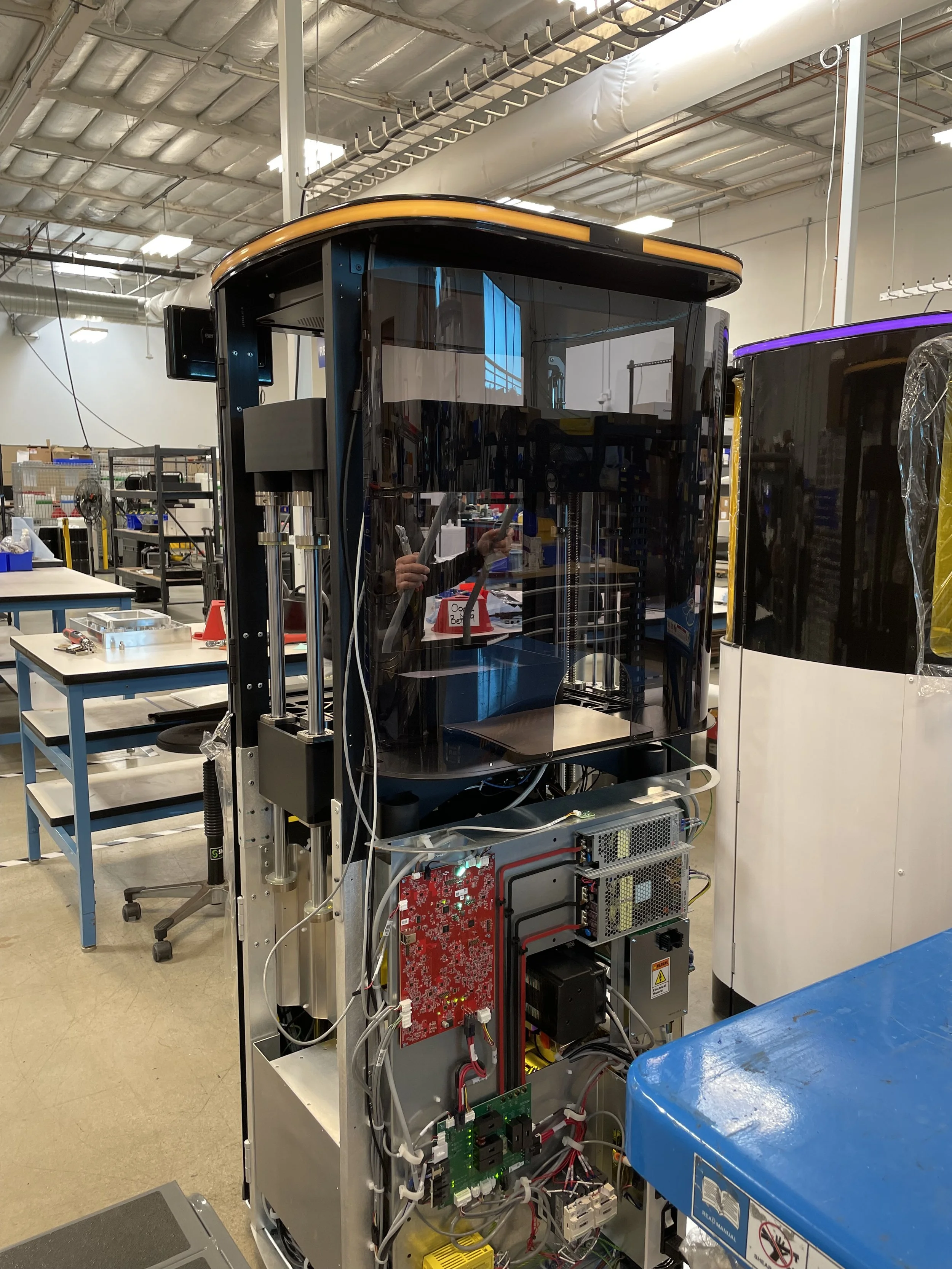

002-003 DESIGN DEVELOPMENT | DFM

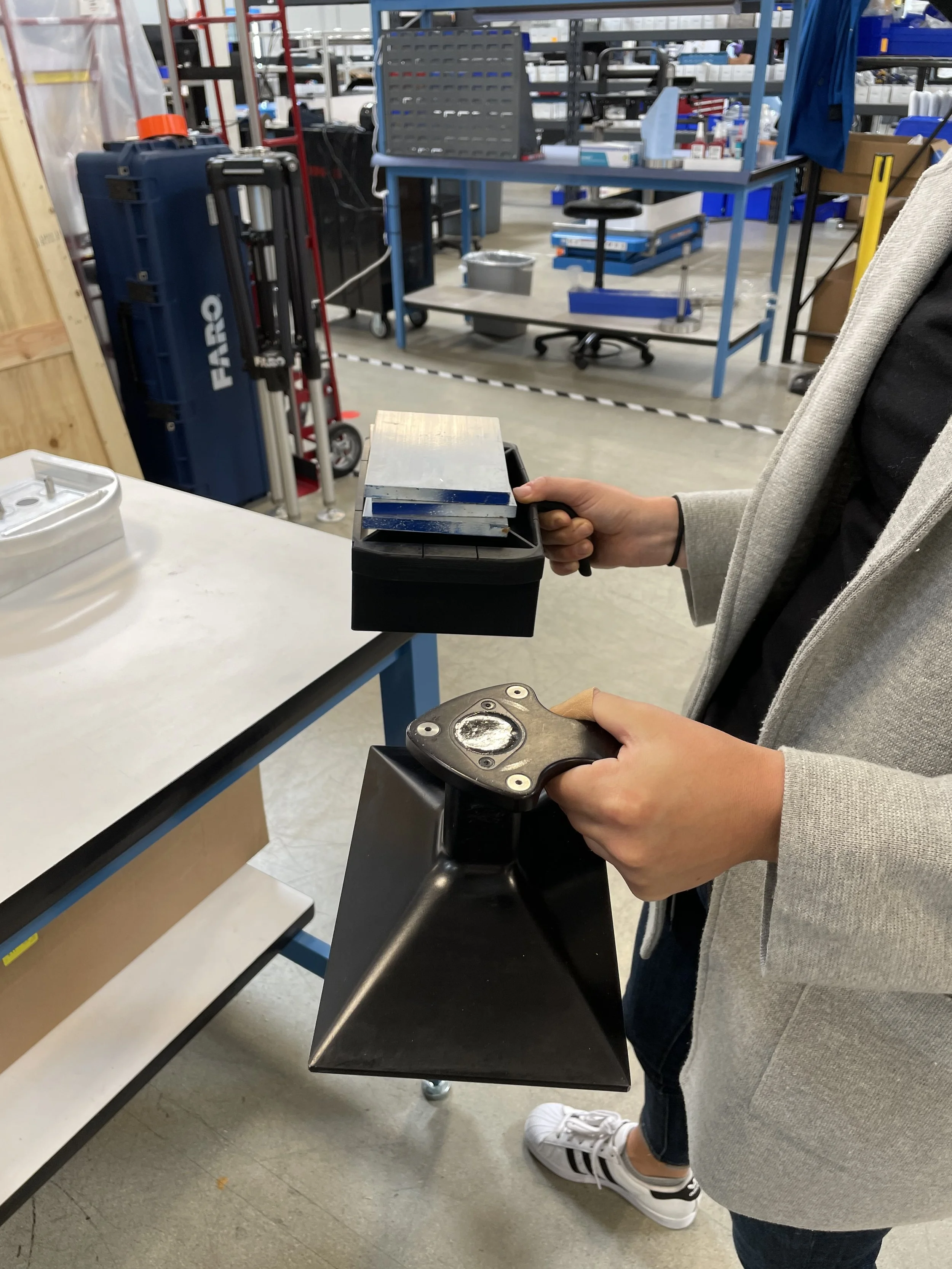

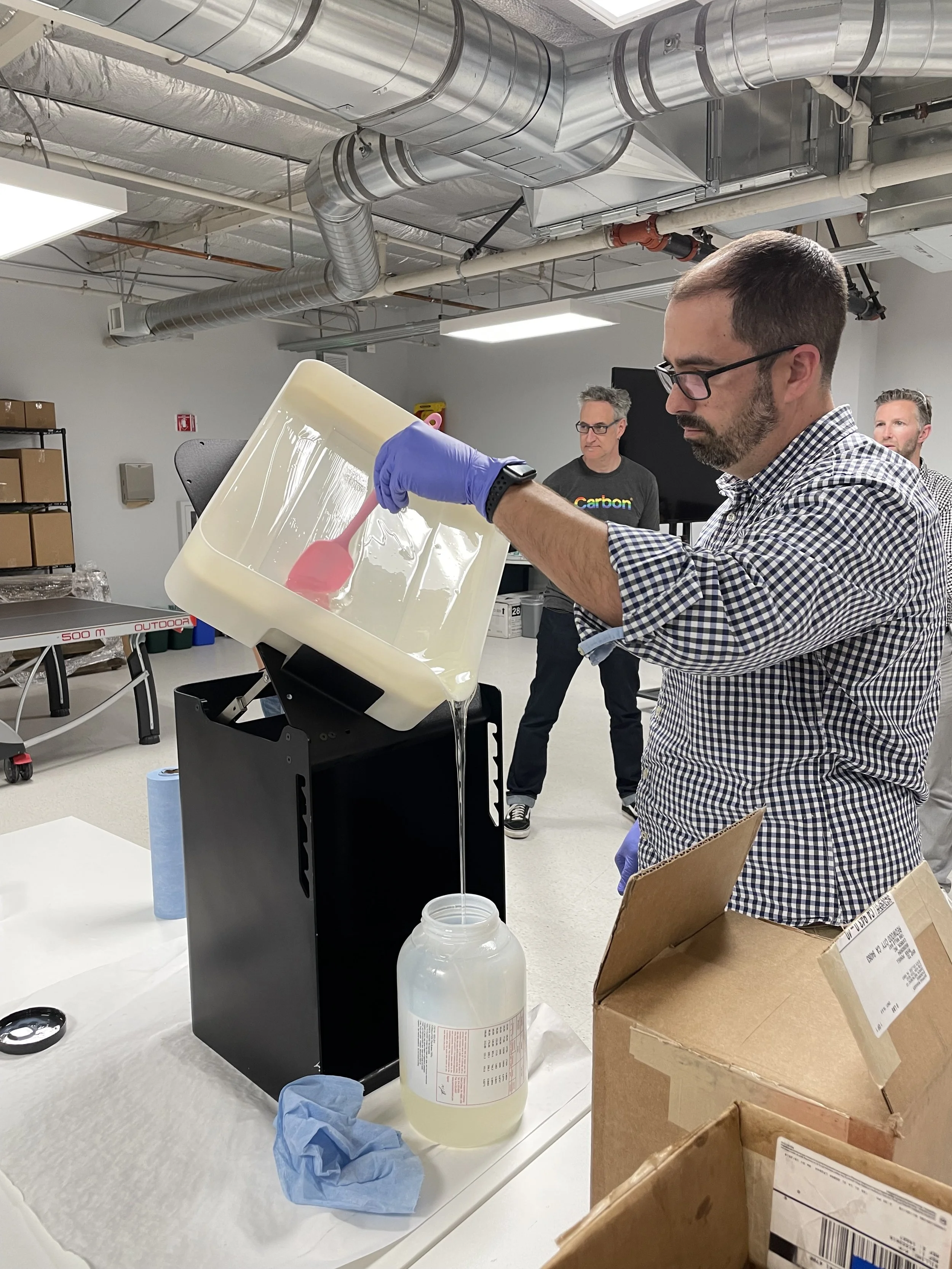

Cassettes & Platforms

M3 and M3 Max lightweight platform for better ergo

M3 Max lightweight cassette for better ergo

Cassette handle and pour spout for better handling and cleaning post pring

Cassette pour stand (legacy) for ease of cleaning and resin swap

Cassette lid for transport and storage

Ergo State for easy part removal

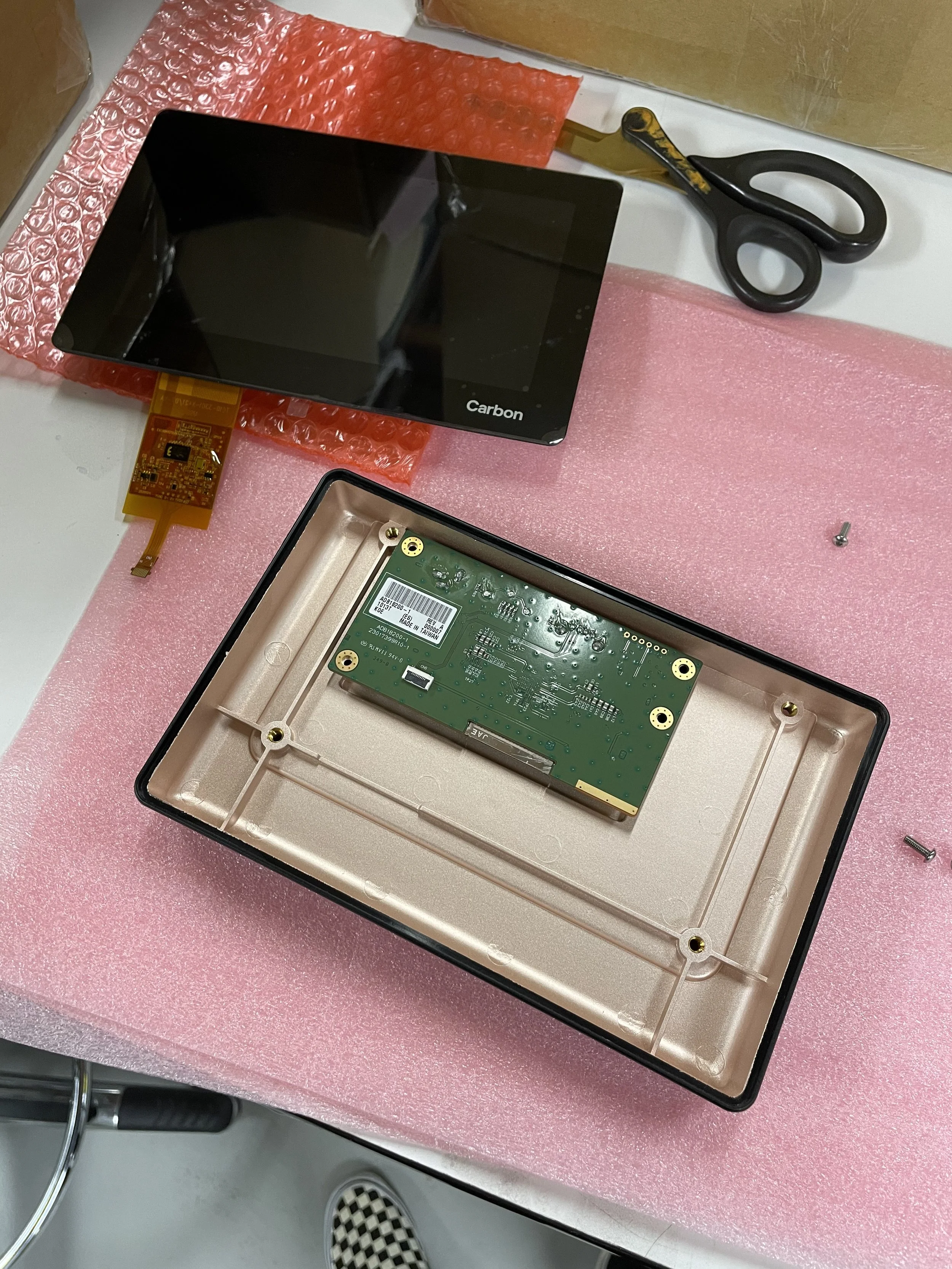

Custom Full-Touch Display

Designed and developed the display module

Defined and sourced the final touch sensor/LCD

EMC/EMI design and support

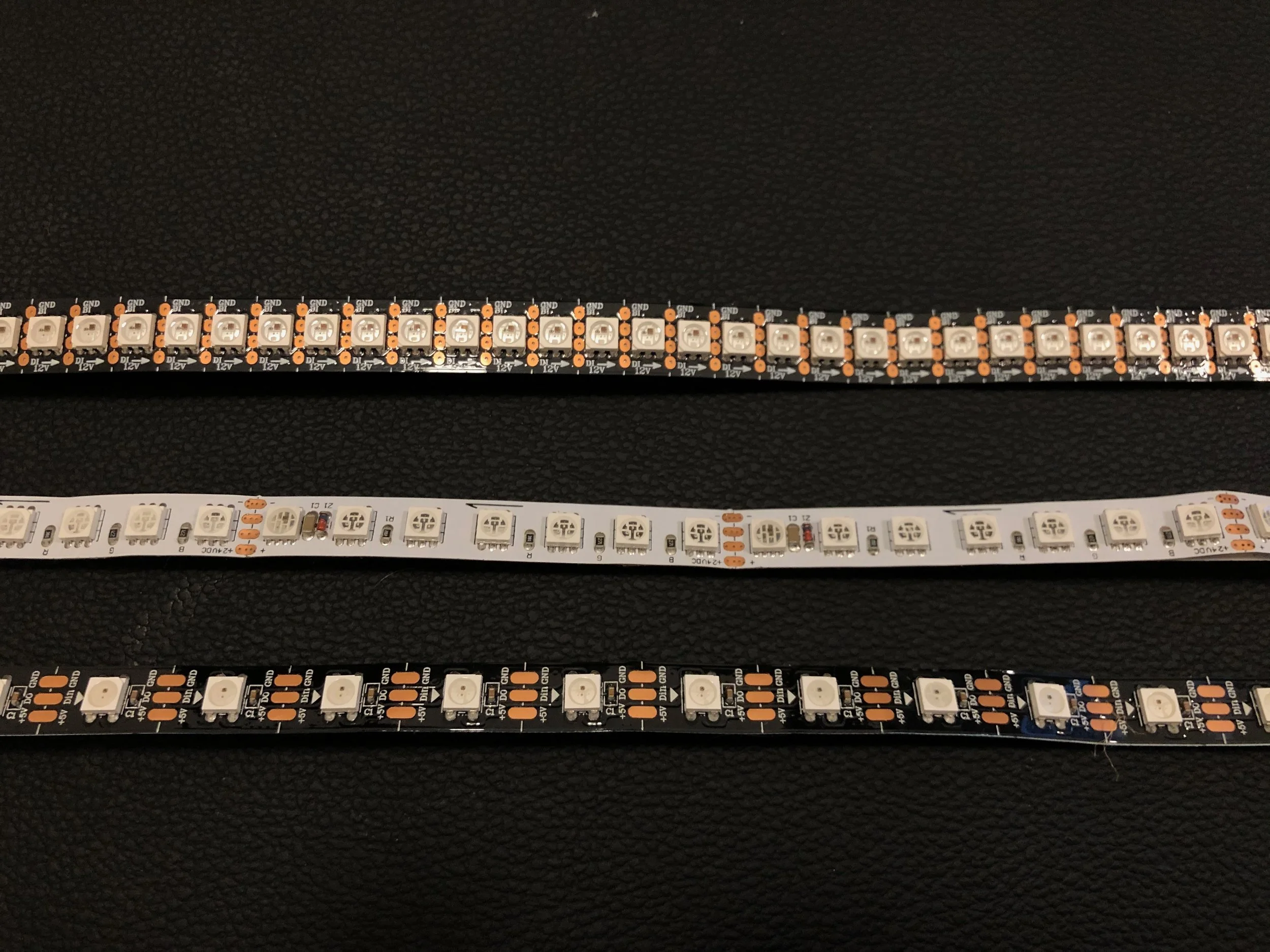

LED Status Indicator Bar

Integrated LED status lighting design

Defined and sourced the final LED strip

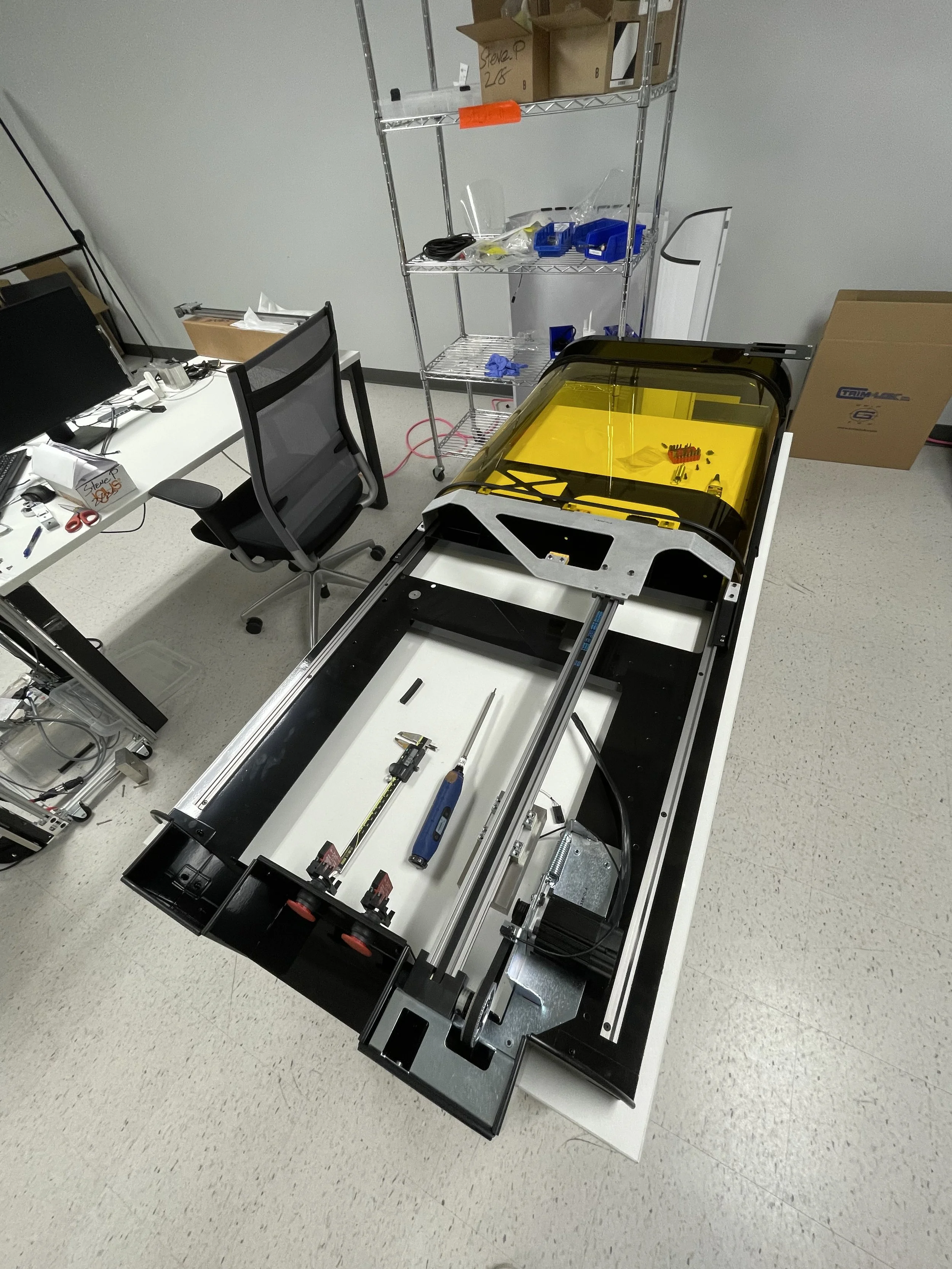

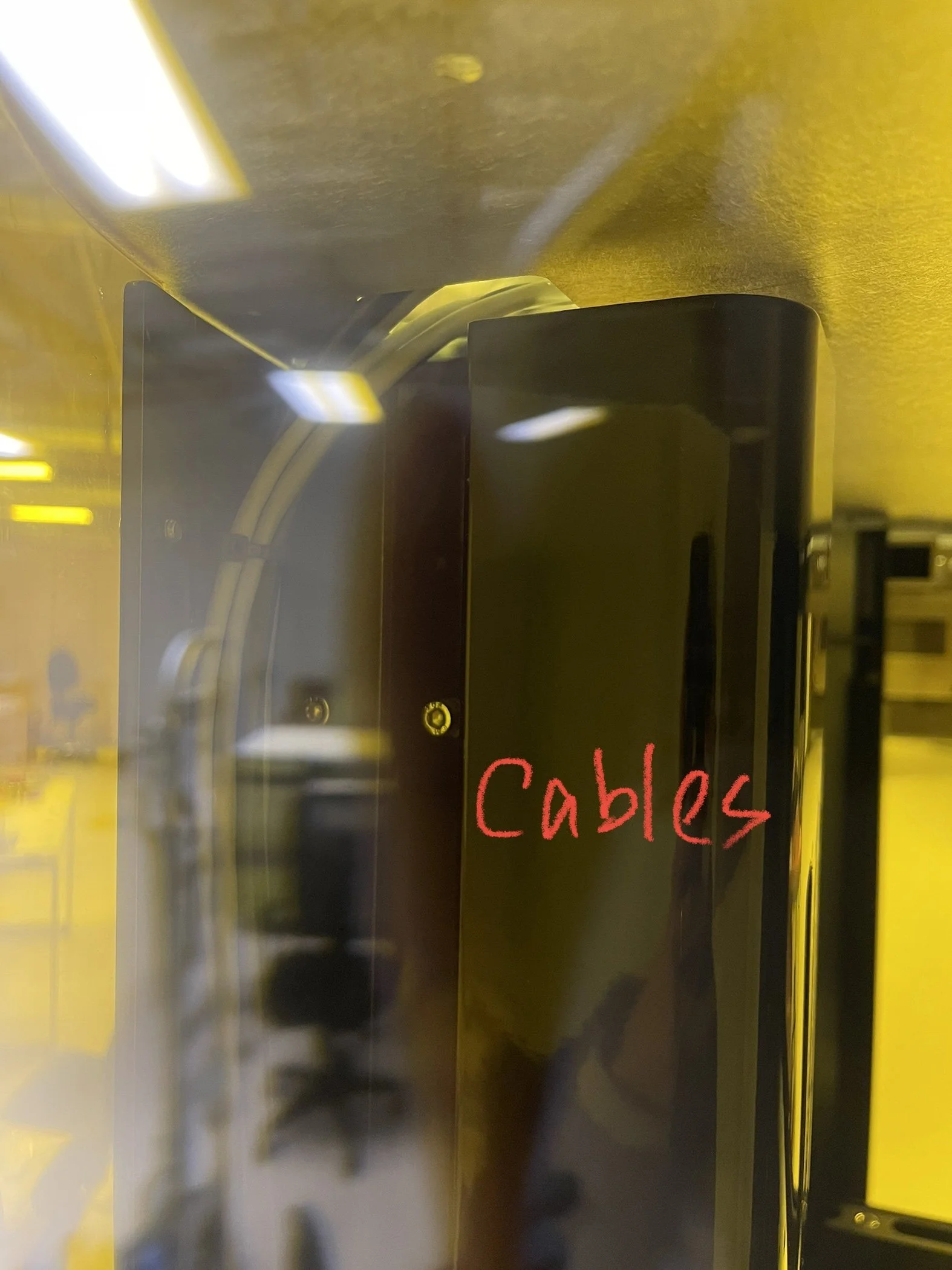

Service access door

Ease of service and access to all internal components

Oxygen, light engine, EE and power

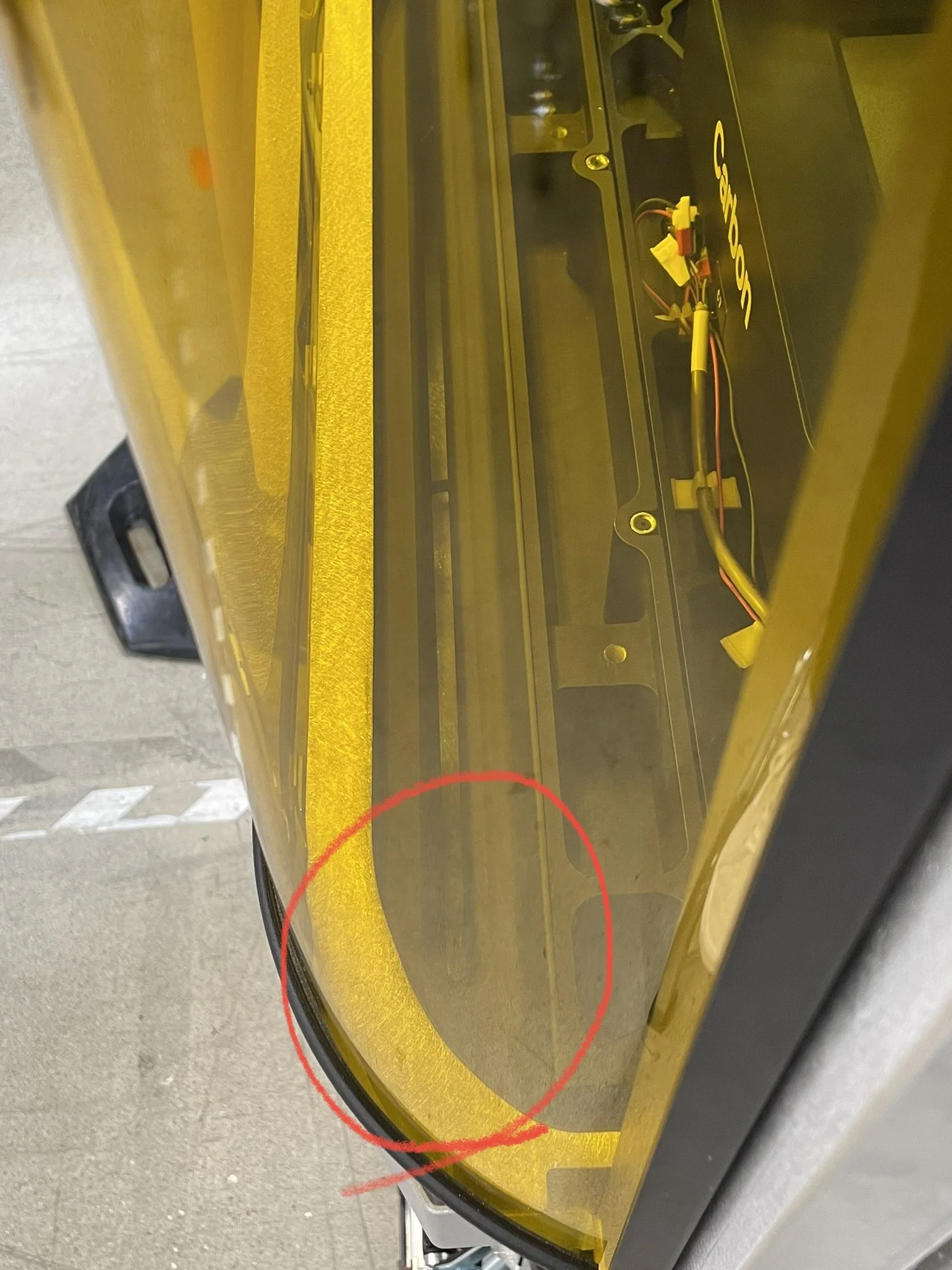

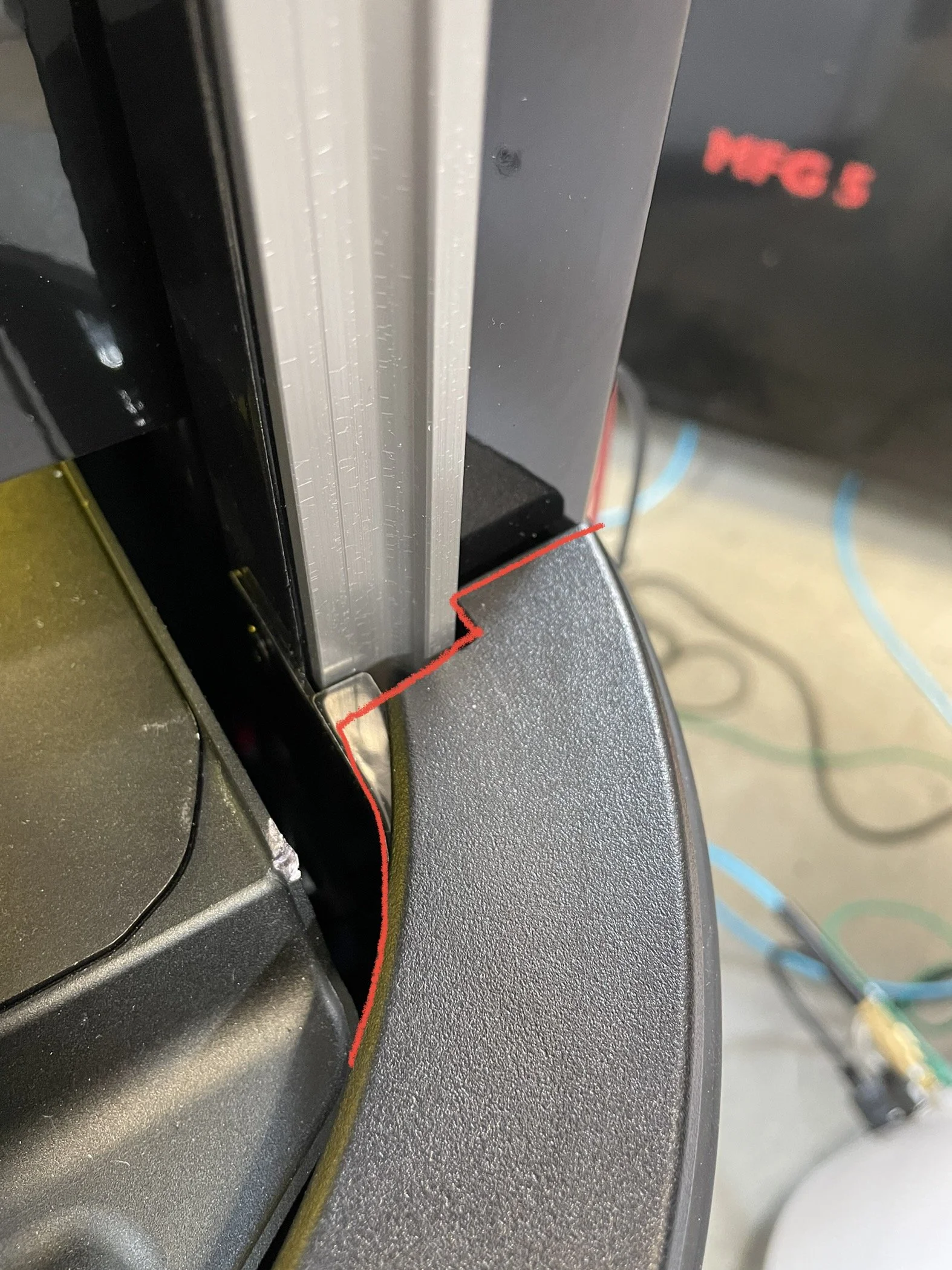

Spill contamination solution on the main deck

Hands free access window design (yellow door)

Custom Sound Design

With Sanctus Audio

Sounds that work well various types of production settings

Sound designs for feedback and printer states

Carbon audio logo design

003 Design For Manufacturing

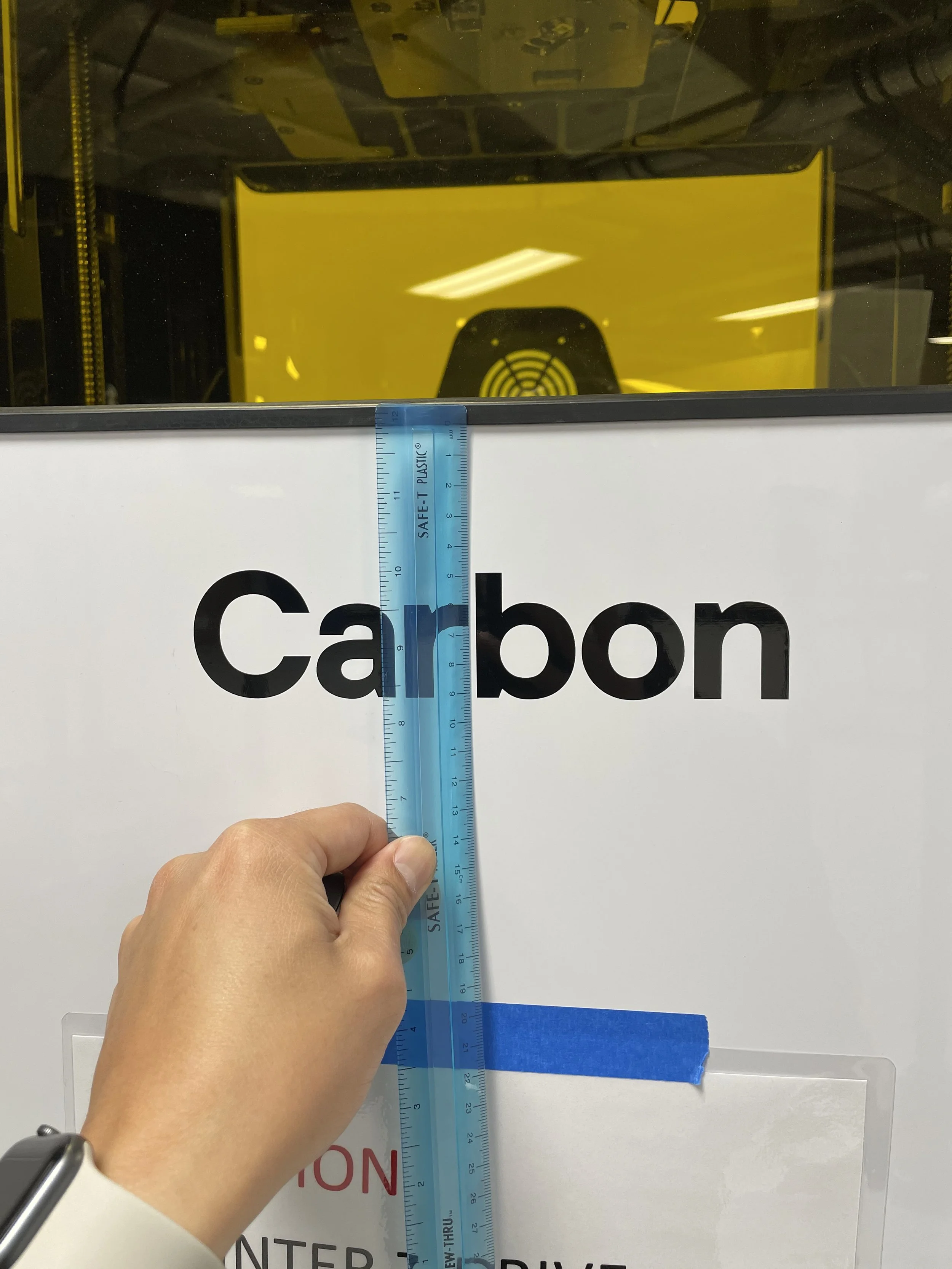

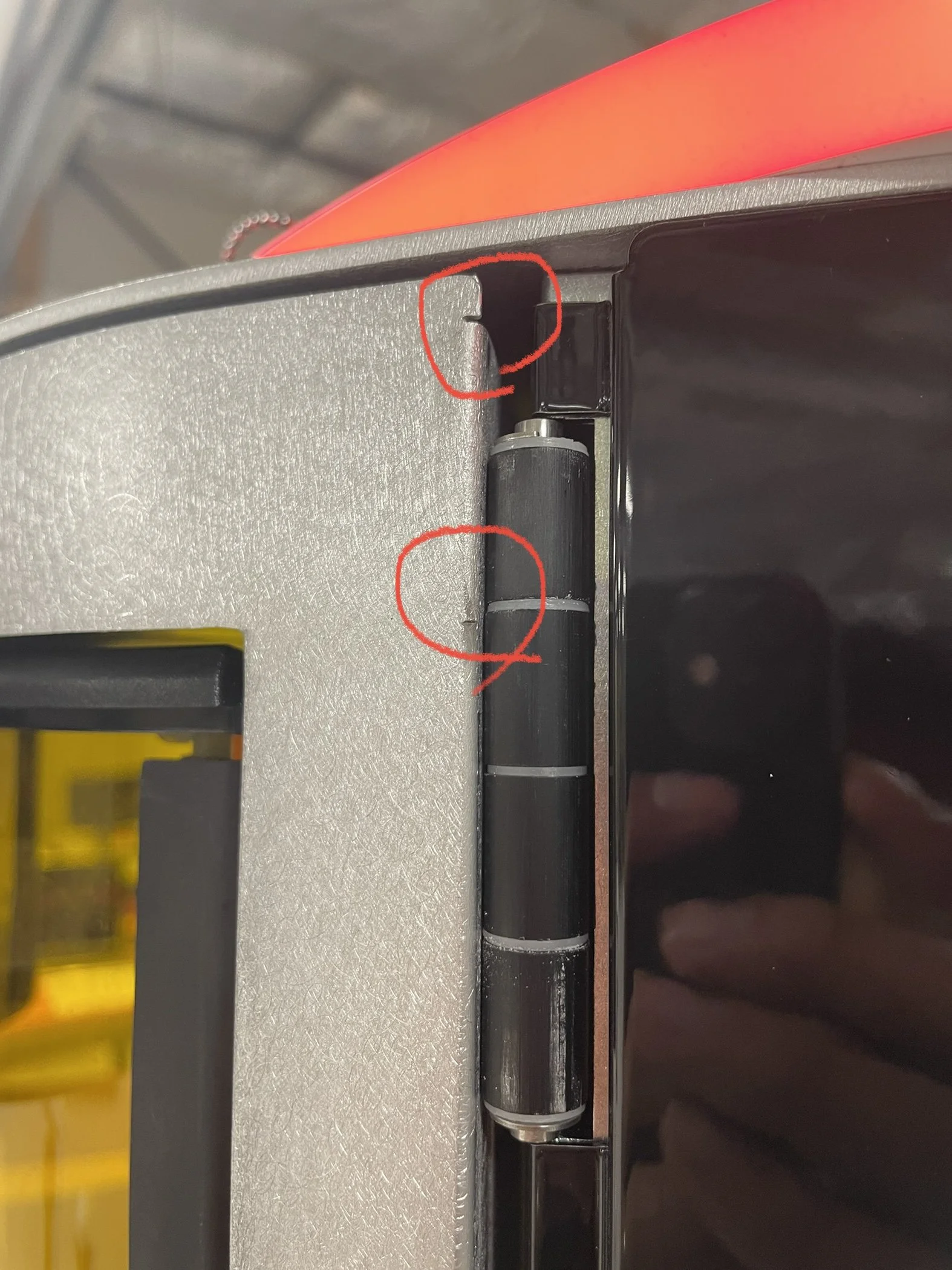

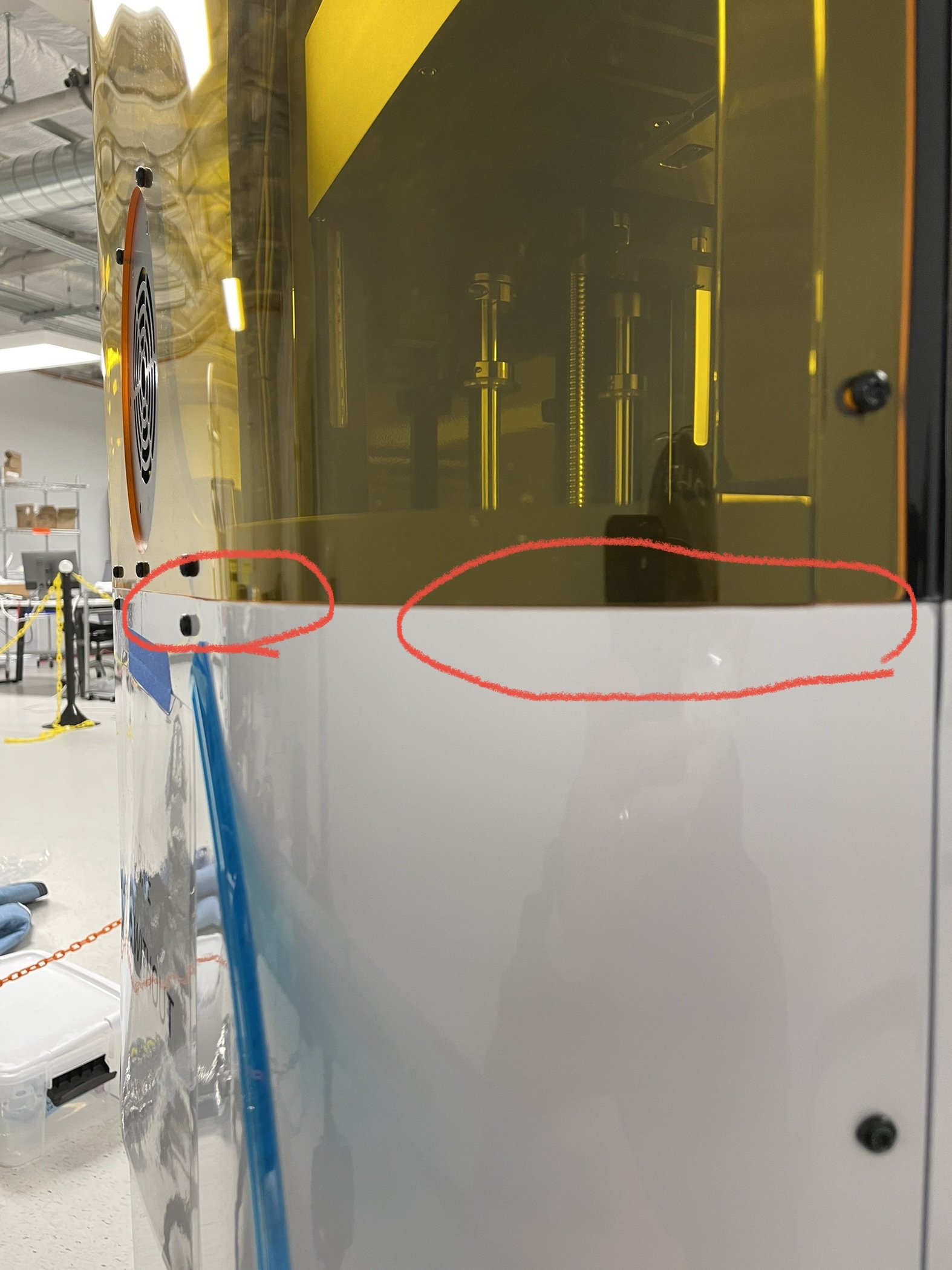

Beta Fab Design Review and QC

Developed a master Cosmetic Spec document for QC

Inspection and QC on all aspects of design

Part fitment

Paint quality, lot to lot color, color matching

Packaging

Quality of all parts

004 PRODUCTION AND FIRST INSTALLS

Carbon M3 & M3 Max

Build area doubled in size

2.2x faster print speed

Higher accuracy and repeatability

Higher yield for first print success